Valves

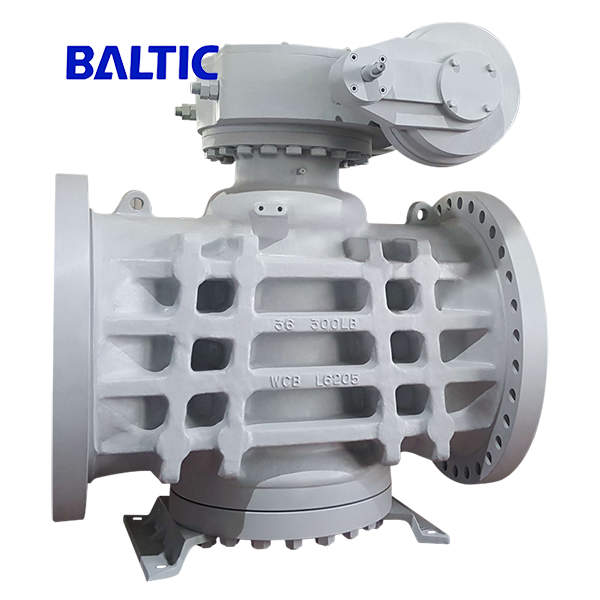

A ball valve is widely used in petroleum refining, long-distance pipeline, chemical industry, paper-making, pharmaceutical, water conservancy, electric power, steel and other industries, and plays an important role in economy.

The ball valve in the pipeline is mainly used to cut off, distribute and change the flow direction of the medium. It only needs to rotate 90 degrees with small torque to close tightly. It is opened when the hole of the ball is in line with the flow and closed when it is pivoted 90-degrees.

According to structure, a ball valve can be classified into three classes: floating ball valves, trunnion mounted ball valves, multi way ball valves.

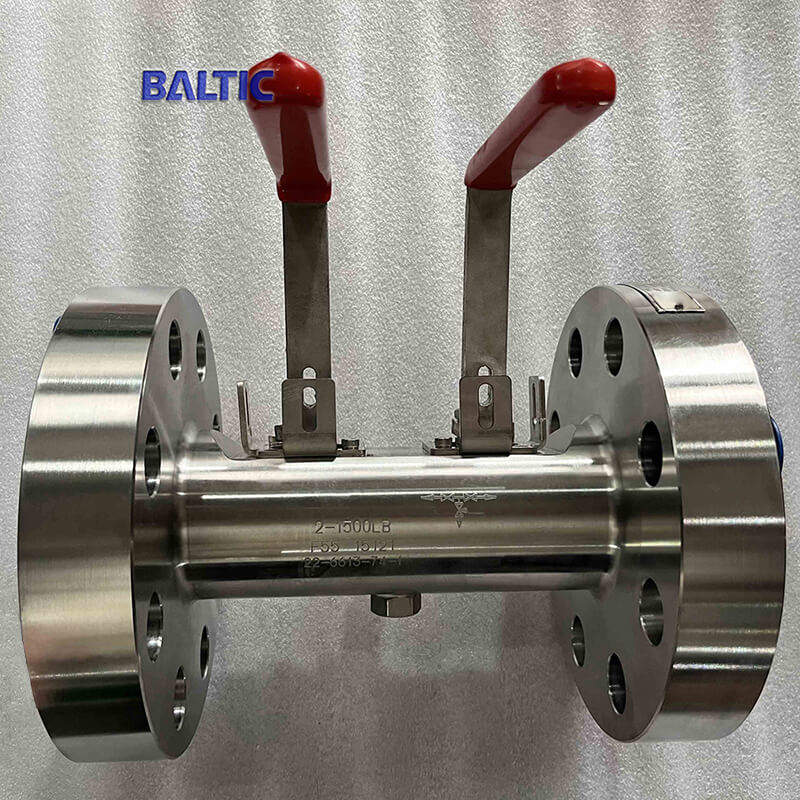

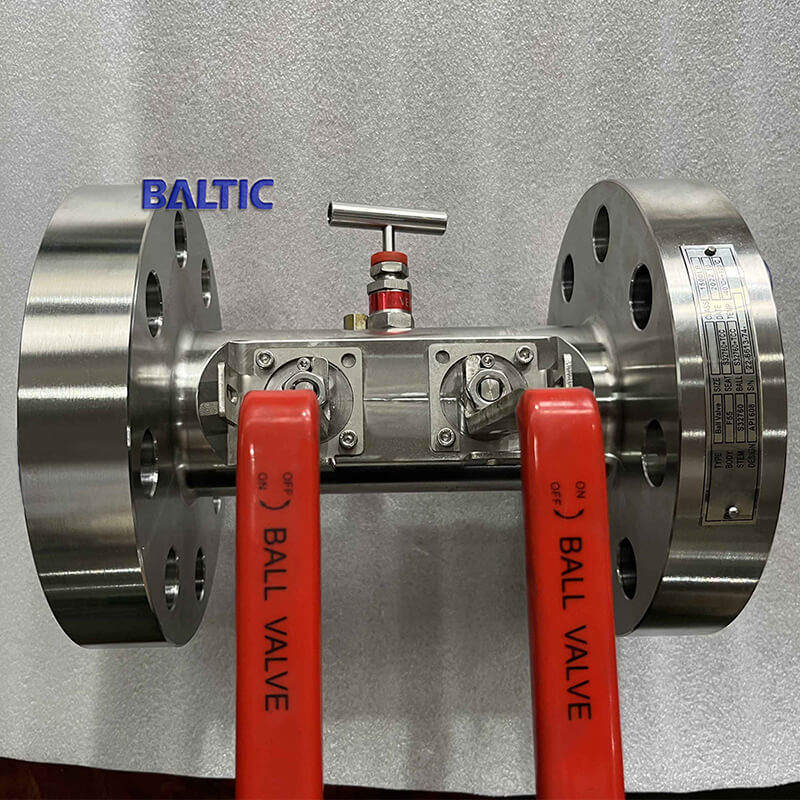

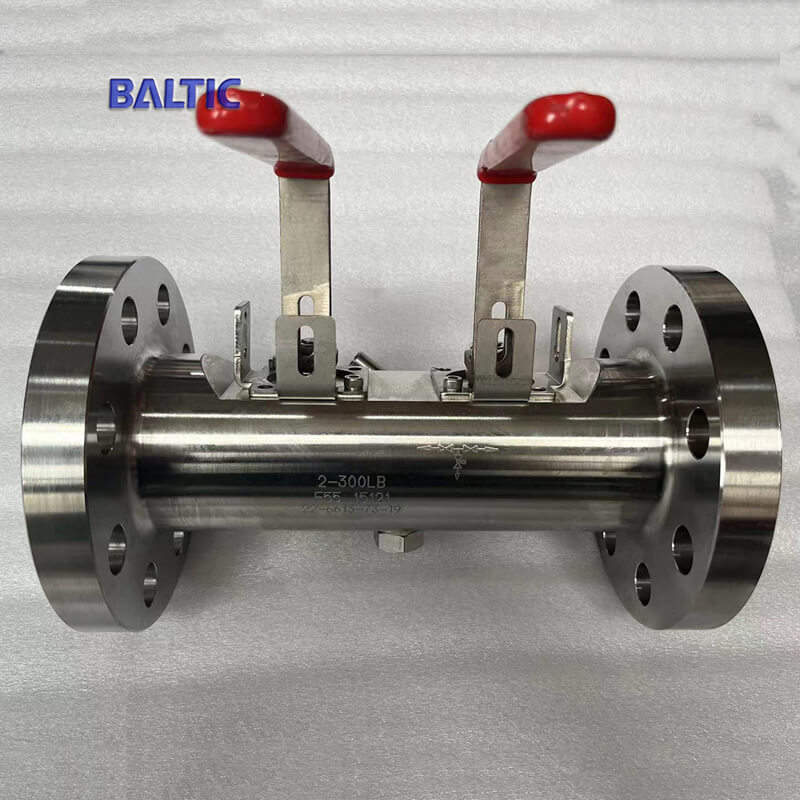

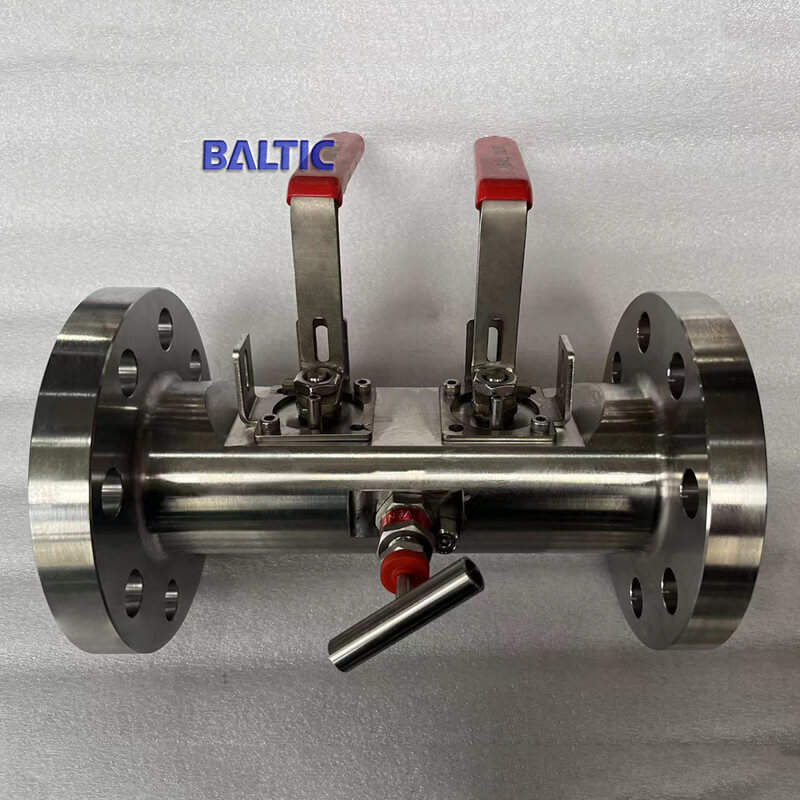

According to connections, the ball valve can fall into flanged ball valves, fully welded ball valves and socket welded ball valves, ring type jointed (RTJ) ball valves.

According to materials used for the body, a ball valve can be divided into casting ball valves, forged ball valves, stainless steel ball valves, etc. According to materials used for the seat, the ball valve can be classified into soft seated ball valves and metal seated ball valves.

According to function, a ball valve falls into single ball valves, DBB ball valves and monoflange ball valves.

If you have any questions about our Ball Valves, pls contact [email protected]!

The ball valve in the pipeline is mainly used to cut off, distribute and change the flow direction of the medium. It only needs to rotate 90 degrees with small torque to close tightly. It is opened when the hole of the ball is in line with the flow and closed when it is pivoted 90-degrees.

According to structure, a ball valve can be classified into three classes: floating ball valves, trunnion mounted ball valves, multi way ball valves.

According to connections, the ball valve can fall into flanged ball valves, fully welded ball valves and socket welded ball valves, ring type jointed (RTJ) ball valves.

According to materials used for the body, a ball valve can be divided into casting ball valves, forged ball valves, stainless steel ball valves, etc. According to materials used for the seat, the ball valve can be classified into soft seated ball valves and metal seated ball valves.

According to function, a ball valve falls into single ball valves, DBB ball valves and monoflange ball valves.

If you have any questions about our Ball Valves, pls contact [email protected]!

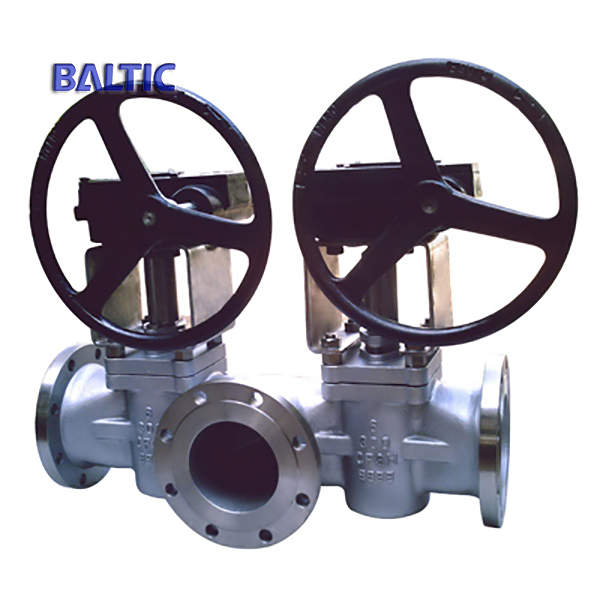

The function of the gate is for opening and closing. Its motion direction is perpendicular to the direction of fluids. The gate valve can only be fully opened and fully closed, and can not be used for flow regulation. Therefore, when the valve is fully open, the flow channel is straight-through and the pressure loss difference is minimum. So gate valves can be used in many conditions.

Check valve is also known as one-way valve or non-return valve. This kind of valve is automatically opened and closed by the force generated by the flow of medium in the pipeline. A check valve is an automatic valve, and mainly applied to the pipe with medium flows in one direction to prevent accident. BALTIC mainly manufactures four types of the check valve: swing check valves, pressure sealing swing check valves, dual plate check valves and tilting disc check valves.

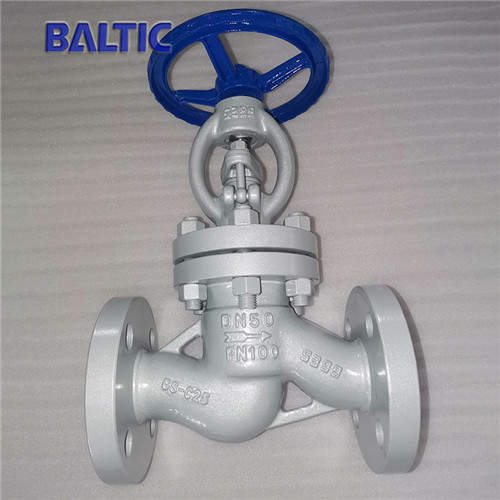

A globe valve is a kind of valve whose closing part (disc) moves along the center line of the valve seat. Because the opening or closing stroke of the valve stem is relatively short, the valve has a very reliable cut-off function, and the change of valve seat opening is proportional to the stroke of the disc, the valve is very suitable to regulate the flow. Therefore, this type of valve is the ideal choice for cutting off or regulating the medium and throttling.

Plug valves are valves which can be opened or closed by rotating 90 degrees to connect or separate the hollow passageway of the plug with that of the valve body.

Its plug can be cylindrical or conical in shape. In the cylindrical plug, the passageway is generally rectangular, while in the conical plug, the passageway is trapezoidal. These shapes make the structure of the plug valve light. It is most suitable for cutting off and connecting medium, and also shunting. But it sometimes can be used for throttling depending on the nature of the application and the erosion resistance of the sealing surface.

1. The plug valve is used for regular operation, and it can be opened and closed quickly and conveniently.

2. The fluid resistance of the plug valve is small.

3. The plug valve has the advantages of simple structure, small volume, light weight and easy maintenance.

4. Good sealing performance.

5. Without the limitation of installation direction, the flow direction of medium can be arbitrary.

6. No vibration and low noise.

Its plug can be cylindrical or conical in shape. In the cylindrical plug, the passageway is generally rectangular, while in the conical plug, the passageway is trapezoidal. These shapes make the structure of the plug valve light. It is most suitable for cutting off and connecting medium, and also shunting. But it sometimes can be used for throttling depending on the nature of the application and the erosion resistance of the sealing surface.

1. The plug valve is used for regular operation, and it can be opened and closed quickly and conveniently.

2. The fluid resistance of the plug valve is small.

3. The plug valve has the advantages of simple structure, small volume, light weight and easy maintenance.

4. Good sealing performance.

5. Without the limitation of installation direction, the flow direction of medium can be arbitrary.

6. No vibration and low noise.

A butterfly valve, also known as flap valve, is a kind of control valve with simple structure. The valve is fully opened and closed when the disc is rotated a quarter turn. And it's a valve that regulates the flow of the medium.

The butterfly valve can be used to control the flow of air, water, steam, various corrosive media, mud, oil, liquid metal and the radiating medium, etc. It is mainly used for cutting off and throttling flow in the pipeline. Disc, mounted on a rod, rotates with the rod to open/close and modulate the fluid passageway.

Advantages:

1. It is convenient and quick to open and close, with low fluid resistance and easy operation.

2. It has simple structure, small size, short structure length, small volume, light weight. And it is suitable for large size valve.

3. It can transport mud and store the least liquid at the pipe port.

4. It has good sealing performance under low pressure.

5. Good regulation performance.

6. When the valve is fully open, the effective flow area of the valve seat passage is large and the fluid resistance is small.

7. The opening and closing torque is small as the both sides of the disc mounted on the rod are basically equal to each other under the action of the medium, and the direction of torque is opposite, so it is easier to open and close.

8. The material of the sealing surface is generally rubber and plastic, so the low-pressure sealing performance is good.

9. Easy to install.

10. The operation is flexible and labor-saving. Manual, electric, pneumatic and hydraulic modes can be selected.

The butterfly valve can be used to control the flow of air, water, steam, various corrosive media, mud, oil, liquid metal and the radiating medium, etc. It is mainly used for cutting off and throttling flow in the pipeline. Disc, mounted on a rod, rotates with the rod to open/close and modulate the fluid passageway.

Advantages:

1. It is convenient and quick to open and close, with low fluid resistance and easy operation.

2. It has simple structure, small size, short structure length, small volume, light weight. And it is suitable for large size valve.

3. It can transport mud and store the least liquid at the pipe port.

4. It has good sealing performance under low pressure.

5. Good regulation performance.

6. When the valve is fully open, the effective flow area of the valve seat passage is large and the fluid resistance is small.

7. The opening and closing torque is small as the both sides of the disc mounted on the rod are basically equal to each other under the action of the medium, and the direction of torque is opposite, so it is easier to open and close.

8. The material of the sealing surface is generally rubber and plastic, so the low-pressure sealing performance is good.

9. Easy to install.

10. The operation is flexible and labor-saving. Manual, electric, pneumatic and hydraulic modes can be selected.

A marine valve is a kind of equipment used to control the pressure, flow rate and flow direction of the fluid in the pipeline to meet environmental conditions of vessels. The valve is the control device of fluid pipeline. Its basic function is to connect or cut off the flow of the medium, change the flow direction of the medium, adjust the pressure and flow rate of the medium to ensure the normal operation of pipes.

Principle:

Depending on the pressure of the valve stem, the sealing surface of the disc and the sealing surface of the seat closely fit together to prevent the flow of the medium.

Advantages:

1. Uncomplicated design, easy manufacture and maintenance.

2. The working stroke is small and the opening and closing time is short.

3. Good sealing performance, small friction between sealing surfaces and long service life.

Principle:

Depending on the pressure of the valve stem, the sealing surface of the disc and the sealing surface of the seat closely fit together to prevent the flow of the medium.

Advantages:

1. Uncomplicated design, easy manufacture and maintenance.

2. The working stroke is small and the opening and closing time is short.

3. Good sealing performance, small friction between sealing surfaces and long service life.

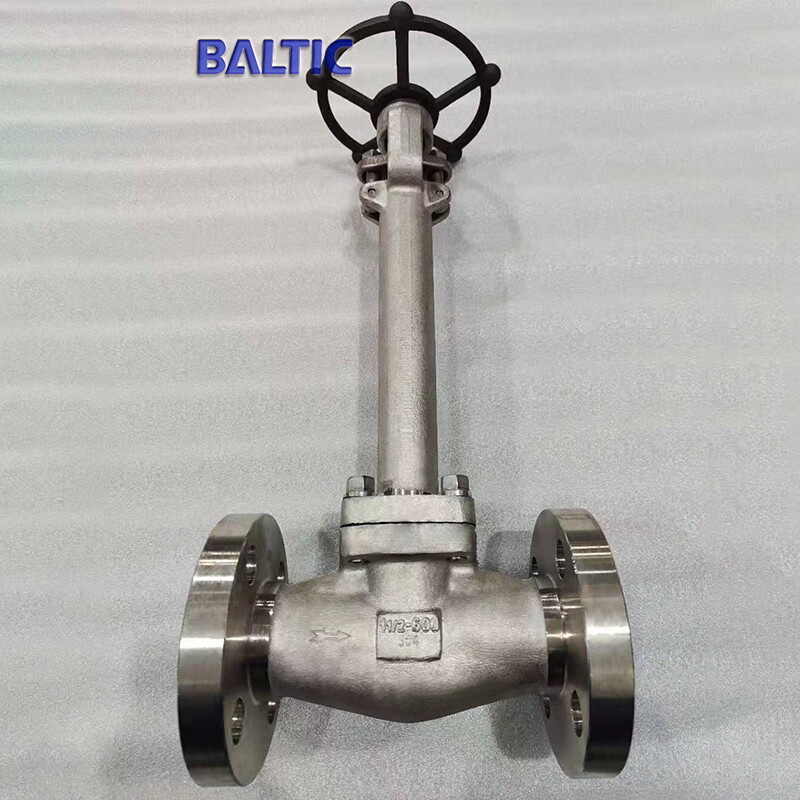

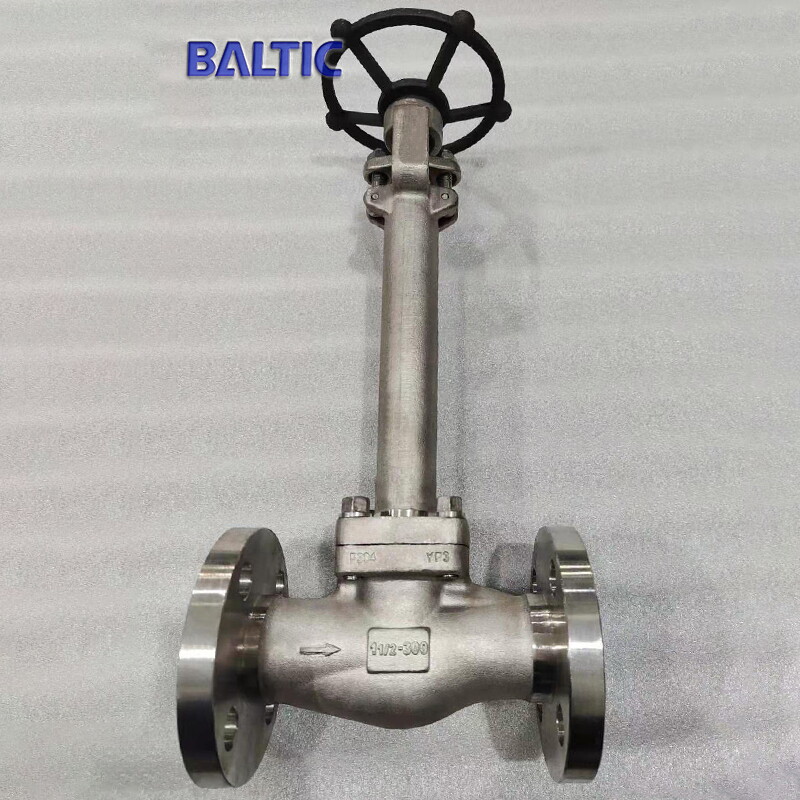

The forging steel valve is mainly used in the pipeline of various systems in thermal power plant for cutting off or connecting the medium. Applicable medium: water, steam and other non-corrosive media. Compared with other valve products, the forged steel valve features high temperature, high pressure and unique self sealing design. The higher the pressure, the more reliable the seal. Due to the special performance, technical characteristics and working conditions, the product can not be replaced by others.

The strainer is an indispensable device on the pipeline conveying medium. It is usually installed in the input end of pressure reducing valve, pressure relief valve, level control valve, and other equipment. The strainer is made of a cylinder, a stainless steel strainer screen, a sewage discharge part, a transmission device and an electrical control part. When the medium passes through the screen, its impurities are blocked. For cleaning, just need to take the removable cartridge out and install it again after treatment. Therefore, the usage and maintenance are very convenient.