The Analysis of the Sealing Force of Titanium Alloy Metal Seated Ball Valves

- Nov Mon, 2022

- Hits: 43

After calculating the sealing force of the titanium alloy metal seated ball valves with a size of 10 inches and pressure 300LB, the finite element analysis for sealing structure of seats is carried out...

Sealing & Calculation of Sealing Force of Titanium Alloy Metal Seated Ball Valves

- Oct Wed, 2022

- Hits: 372

The sphere and valve seat of the ball valve are generally made from titanium alloy due to process characteristics of the PTA device such as high temperature, high pressure and corrosion, and a metal hard...

Titanium Alloy Hard-sealed Ball Valves for PTA

- Oct Sat, 2022

- Hits: 35

PTA is ethylene terephthalate, which is mainly used in the production of polyester. Polyester is the most important variety of synthetic fibers, accounting for nearly 80% of the world's total output...

Practice and Analysis of DBB Valves for Tank Valves (Part Two)

- Sep Sat, 2022

- Hits: 11

2.2 Closing of the tank root valve (DBB) and opening of the operating valve (gate valves) According to the source of unloading, the pipeline for receiving oil for the tank usually has two or more channels....

Practice and Analysis of DBB Valves for Tank Valves (Part One)

- Sep Mon, 2022

- Hits: 16

Abstract: There has been a controversy in the industry on the use of light slab gate valves or DBB valves at the root of the storage tank for a long time. Combine the actual application of the oil depot...

The Sealing Forms and Principles of Power Station Valves

- Aug Fri, 2022

- Hits: 12

With the continuous progress of science and technology and the rapid development of the social economy, all walks of life in China have also faced new opportunities and new challenges. The power station...

Test Methods of Reliability of Valves

- Aug Fri, 2022

- Hits: 14

According to different valve types and different use positions of marine valves, their stress sources are different. Taking the most widely used globe valves among marine valves as an example, the reliability...

The Main Failures of the Valve

- Jul Fri, 2022

- Hits: 6

A marine valve is a common mechanical product in marine products. The failure of valves directly affects the normal operation of system equipment, and even leads to catastrophic consequences. Therefore,...

The Application of DBB Ball Valves to Offshore Oil Platforms

- Jun Wed, 2022

- Hits: 39

Abstract: Since offshore platforms have strict requirements in terms of space, quality and safety, a new type of integrated DBB valve came into being. The sealing principle and structural form of DBB...

Causes and Measures of Defects of Heavy Hammer Check Valves

- May Thu, 2022

- Hits: 7

Descriptions and causes of defects After a long-term operation, the main defects and causes of the heavy hammer check valve are shown in Table 1. Table 1 Defects and causes of heavy hammer check...

The Structure, Working Principle & Selection of Heavy Hammer Check Valves

- May Mon, 2022

- Hits: 12

Check valves are widely used in industrial factories. Lift check valves, swing check valves, butterfly check valves and diaphragm check valves have their advantages and disadvantages, which should be...

Pickling Passivation of Austenitic Stainless Steel Valves

- Apr Tue, 2022

- Hits: 229

Pickling passivation The corrosion rate is significantly lower than that without any treatment after the metal acting with an oxidizing medium, which is called passivation of the metal. The passivation...

Structural Design & Optimization of Limit Locking of Ball Valves

- Apr Tue, 2022

- Hits: 57

1. Overview A ball valve is a kind of rotary valve with a ball as the opening and closing part. The main driving modes of ball valves are manual, electric,...

Problems Existing in the Fault Diagnosis Technology for Valves

- Mar Wed, 2022

- Hits: 5

Detection accuracy for the valve state parameter is not high. Measuring the state parameters of the valve is the basis for valve fault diagnosis, but some detection methods and equipment currently have...

The Current Situation of the Valve

- Mar Fri, 2022

- Hits: 13

A valve is an important fluid control device in the industry, involving all walks of life, especially petroleum and petrochemical, liquid transportation and other industries. The emergence of...

DBB and DIB Valves

- Feb Mon, 2022

- Hits: 185

There are two sealing structures of common seats for trunnion mounted ball valves. (1) DBB valves (double block and bleed valves) DBB valves are valves that have two...

Solutions to Internal Leakages of Plug Valves

- Jan Thu, 2022

- Hits: 17

The ESD high-pressure vent pipe in the station yard is under long-term single sided pressure on the plug valve. The working condition is harsh and frequent internal leakage occurs, and...

Forced Sealed Valves for Natural Gas Pipelines

- Dec Mon, 2021

- Hits: 20

A forced sealed valve is also known as a double block and double bleed valve, which was first used for oil depots in the airport, and was mainly used in metering systems,...

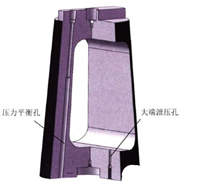

The Structural Characteristics of the Pressure-balanced Plug Valve

- Nov Fri, 2021

- Hits: 86

The features of the plug valve The plug valve uses a plunger body with a through hole as an opening and closing part, and the plunger body rotates 90° with the valve stem to realize the function...

Kinetic Analysis and Reliability of Pneumatic Cryogenic Gate Valves with Open Spheres

- Oct Fri, 2021

- Hits: 10

The kinetic analysis and reliability demonstration of the main parts of the gate valve under low-temperature conditions have provided a theoretical basis for the development and application of the...