Practice and Analysis of DBB Valves for Tank Valves (Part One)

Abstract: There has been a controversy in the industry on the use of light slab gate valves or DBB valves at the root of the storage tank for a long time. Combine the actual application of the oil depot of Shenzhen Chengyuan Aviation Oil Co., Ltd. to compare the two different valves and summarize the practical experience in this article.

The national safety production supervision department defines the tank valve as an emergency valve, and it needs to be as close as possible to the storage tank. When a fire occurs in the storage tank, the valve can quickly and effectively isolate the storage tank and prevent the fire from spreading. In addition, the valve body and sealing should have excellent fire resistance, especially to avoid the failure of the main seal between the wedge and the valve seat due to fire.

1. The structure principle and fire resistance of the valve

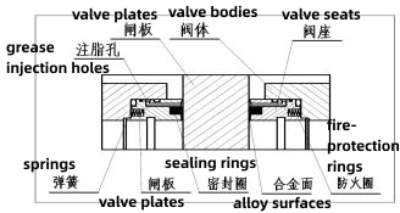

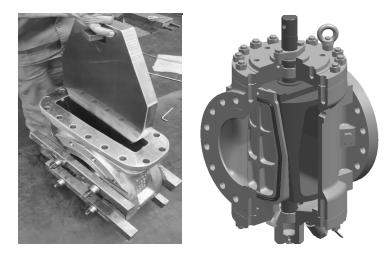

Relative to DBB valves, light slab gate valves belong to the gate valve. It has light weights, fireproof sealing performance, simple transmission structure. Its action speed depends on the selection of actuators, including electric, pneumatic or electric and hydraulic actuators and the improvement of mechanical properties of transmission parts. A light slab gate valve is more suitable as an emergency valve in the tank root position, because it can be closed in one minute manually. When the valve is closed, the actuator acts directly on the wedge through the valve stem (lifting nuts), pushes the wedge’s PTFE seal against the valve seat at the outlet, and compresses it until the wedge matches the metal sealing surface on the valve seat, thus forming a double sealing. There is a PTFE-to-metal seal, then a metal-to-metal seal, figure 1. In the event of a fire in the storage tank, even if the PTFE seal is burnt, the spring will automatically return, and the metal sealing structure can play second protection; the stainless steel wedge is thicker than the DBB valve (as shown in Figure 2), and only little deformation occurs when heated. As an emergency valve with infrequent operation, the light slab gate valve is characterized by excellent emergency performance and low costs.

Figure 1 Working principles of the sealing of light slab gate valves

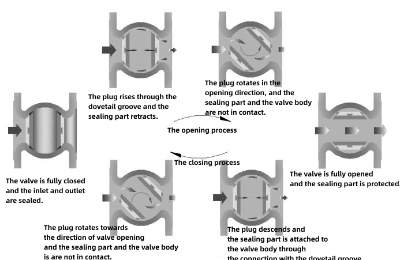

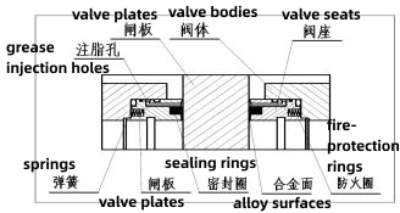

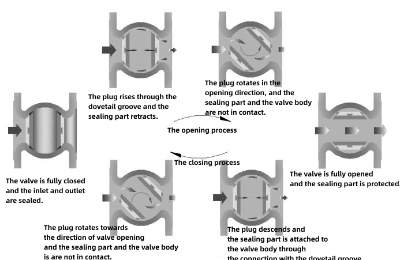

Compared with light slab gate valves, DBB valves are plug valves. Their advantages are that the friction and torque are relatively small, and the manual operation is easy. However, the transmission structure is complex, and the action speed is limited by the internal structure, a DBB valve is more suitable for frequent operations. When the valve is closed, the actuator pushes the sealing slip sheet through the plug to be closed to the valve body, and its rubber seal generates a certain amount of compression deformation to achieve sealing (as shown in Figure 3). In the event of a fire, if the rubber seal fails, the position of the rubber sealing ring will form a gap. Without double sealing, the fire may spread, and the fire resistance of a DBB valve is not as reliable as the double sealing of the gate valve. In addition, in the closing process of the DBB valve, the cock has a switching between vertical and horizontal movement, and its quick closing is limited, which is not as good as the modified gate valve such as electro-hydraulic or gas-liquid valves. As an emergency valve with infrequent action, the fire performance of DBB valves is not as good as that of gate valves, and the cost is higher.

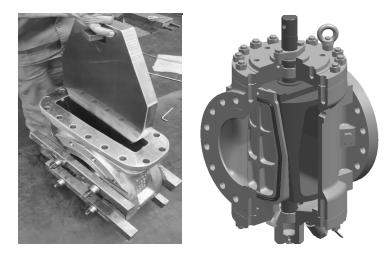

Figure 2 A comparison of valve wedges of light slab gate valves and DBB valves

2. Daily operation management

The advent of the DBB valve has replaced the cumbersome design of the two-way manual gate valve in the past, so it is a labor-intensive alternative, not a necessity. In daily operation, the tank root valve should not be used as a working valve (with frequent action); it should be kept in a normally open state, and daily maintenance should be done to prevent the wear of components and reduce the sealing performance, and ensure that it can be closed quickly and effectively in an emergency state. If the DBB valve is used as both the tank root valve and the working valve, or the DBB valve is used as the tank root valve and the light slab gate valve the operating valve, the first valve of the tank root needs to be kept normally closed every day. There will be maintenance and other issues, and the cost of investment is relatively high. The following are a few examples to illustrate.

2.1 The often closing of the DBB valve and gate valve

There are problems that the pressure between the two valves and the safety valve of the pipe gallery cannot be released to the storage tank, and the metal hose is originally a weak point for bearing pressure, so this mode is not desirable.

Figure 3 The working principle of the sealing of the DBB valve

The national safety production supervision department defines the tank valve as an emergency valve, and it needs to be as close as possible to the storage tank. When a fire occurs in the storage tank, the valve can quickly and effectively isolate the storage tank and prevent the fire from spreading. In addition, the valve body and sealing should have excellent fire resistance, especially to avoid the failure of the main seal between the wedge and the valve seat due to fire.

1. The structure principle and fire resistance of the valve

Relative to DBB valves, light slab gate valves belong to the gate valve. It has light weights, fireproof sealing performance, simple transmission structure. Its action speed depends on the selection of actuators, including electric, pneumatic or electric and hydraulic actuators and the improvement of mechanical properties of transmission parts. A light slab gate valve is more suitable as an emergency valve in the tank root position, because it can be closed in one minute manually. When the valve is closed, the actuator acts directly on the wedge through the valve stem (lifting nuts), pushes the wedge’s PTFE seal against the valve seat at the outlet, and compresses it until the wedge matches the metal sealing surface on the valve seat, thus forming a double sealing. There is a PTFE-to-metal seal, then a metal-to-metal seal, figure 1. In the event of a fire in the storage tank, even if the PTFE seal is burnt, the spring will automatically return, and the metal sealing structure can play second protection; the stainless steel wedge is thicker than the DBB valve (as shown in Figure 2), and only little deformation occurs when heated. As an emergency valve with infrequent operation, the light slab gate valve is characterized by excellent emergency performance and low costs.

Figure 1 Working principles of the sealing of light slab gate valves

Compared with light slab gate valves, DBB valves are plug valves. Their advantages are that the friction and torque are relatively small, and the manual operation is easy. However, the transmission structure is complex, and the action speed is limited by the internal structure, a DBB valve is more suitable for frequent operations. When the valve is closed, the actuator pushes the sealing slip sheet through the plug to be closed to the valve body, and its rubber seal generates a certain amount of compression deformation to achieve sealing (as shown in Figure 3). In the event of a fire, if the rubber seal fails, the position of the rubber sealing ring will form a gap. Without double sealing, the fire may spread, and the fire resistance of a DBB valve is not as reliable as the double sealing of the gate valve. In addition, in the closing process of the DBB valve, the cock has a switching between vertical and horizontal movement, and its quick closing is limited, which is not as good as the modified gate valve such as electro-hydraulic or gas-liquid valves. As an emergency valve with infrequent action, the fire performance of DBB valves is not as good as that of gate valves, and the cost is higher.

Figure 2 A comparison of valve wedges of light slab gate valves and DBB valves

2. Daily operation management

The advent of the DBB valve has replaced the cumbersome design of the two-way manual gate valve in the past, so it is a labor-intensive alternative, not a necessity. In daily operation, the tank root valve should not be used as a working valve (with frequent action); it should be kept in a normally open state, and daily maintenance should be done to prevent the wear of components and reduce the sealing performance, and ensure that it can be closed quickly and effectively in an emergency state. If the DBB valve is used as both the tank root valve and the working valve, or the DBB valve is used as the tank root valve and the light slab gate valve the operating valve, the first valve of the tank root needs to be kept normally closed every day. There will be maintenance and other issues, and the cost of investment is relatively high. The following are a few examples to illustrate.

2.1 The often closing of the DBB valve and gate valve

There are problems that the pressure between the two valves and the safety valve of the pipe gallery cannot be released to the storage tank, and the metal hose is originally a weak point for bearing pressure, so this mode is not desirable.

Figure 3 The working principle of the sealing of the DBB valve