Types of Plug Valves

Plug valves have lubricated and non-lubricated designs and are with various types of port openings through the plugs.

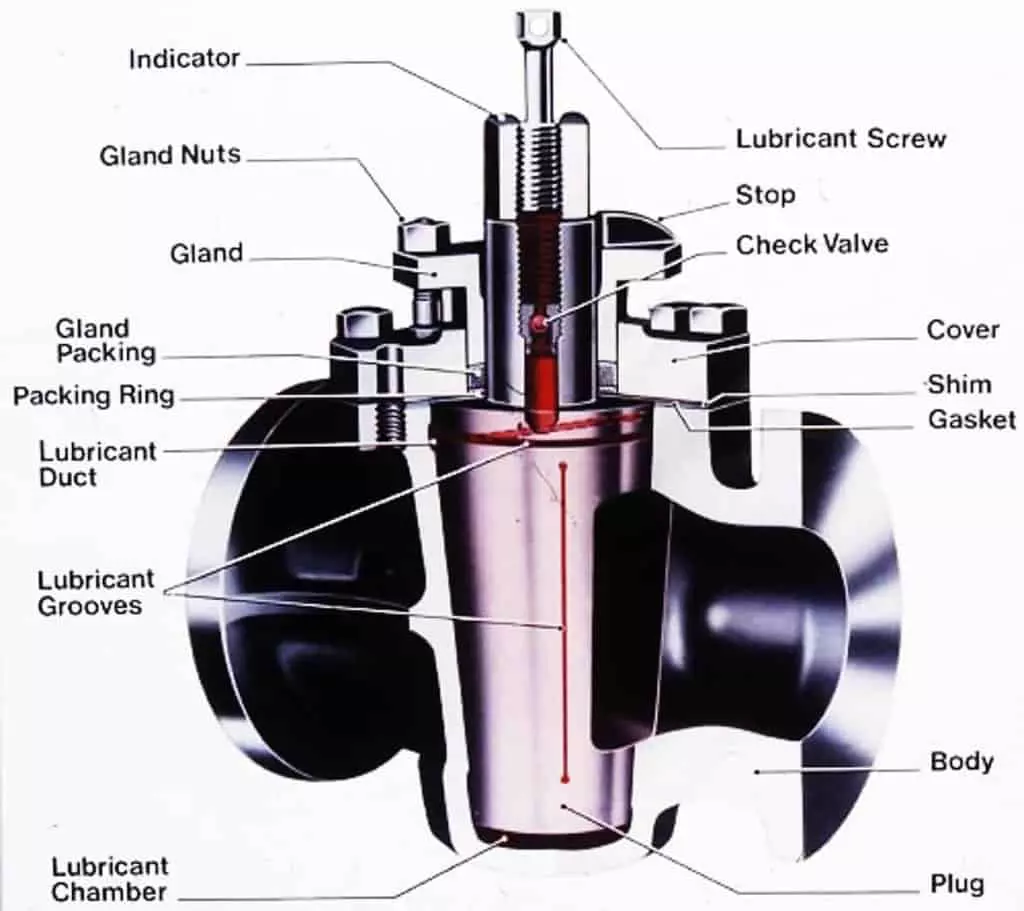

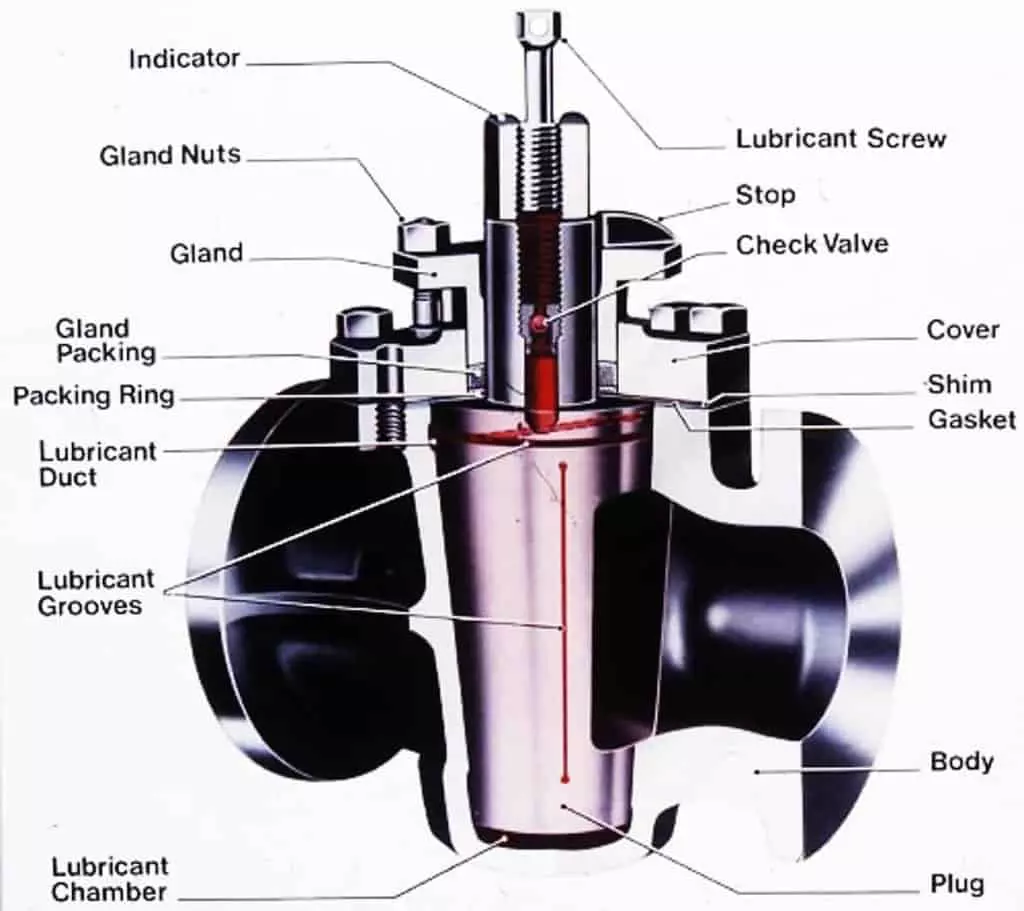

Lubricated Plug Valve

The plug in a lubricated plug valve has a cavity in the middle along its axis. You can see this in the image. The lubricant chamber at the bottom and the sealant injection device at the top ensure the supply of lubricant.

In case the sealant is injected into the cavity, a check valve is below the injection fitting to prevent the sealant from flowing in the opposite direction.

The plug surface is continuously lubricated by the sealant, which enters the lubricant groove on the plug surface from the center cavity through radial holes. Why do we need all this? Many plug valves are of metal construction.

The narrow gap around the plug may cause leakage. If the gap is further reduced, friction will increase and the plug may become stuck in the valve body.

Lubricant reduces the force required to open or close the valve and allows the plug to move smoothly. Lubricants also prevent plug corrosion.

Lubricant materials must be compatible with pipeline fluids. They should not be dissolved or washed away by flow media. Otherwise, they may contaminate the fluid and damage the seal between the plug and the valve body, causing leakage. In addition, the sealant used must be able to resist the temperature of flow media.

The lubricated plug valve has a large size range and is suitable for working in high pressure and high temperature environment. These valves are less worn and have better corrosion resistance in certain service environments.

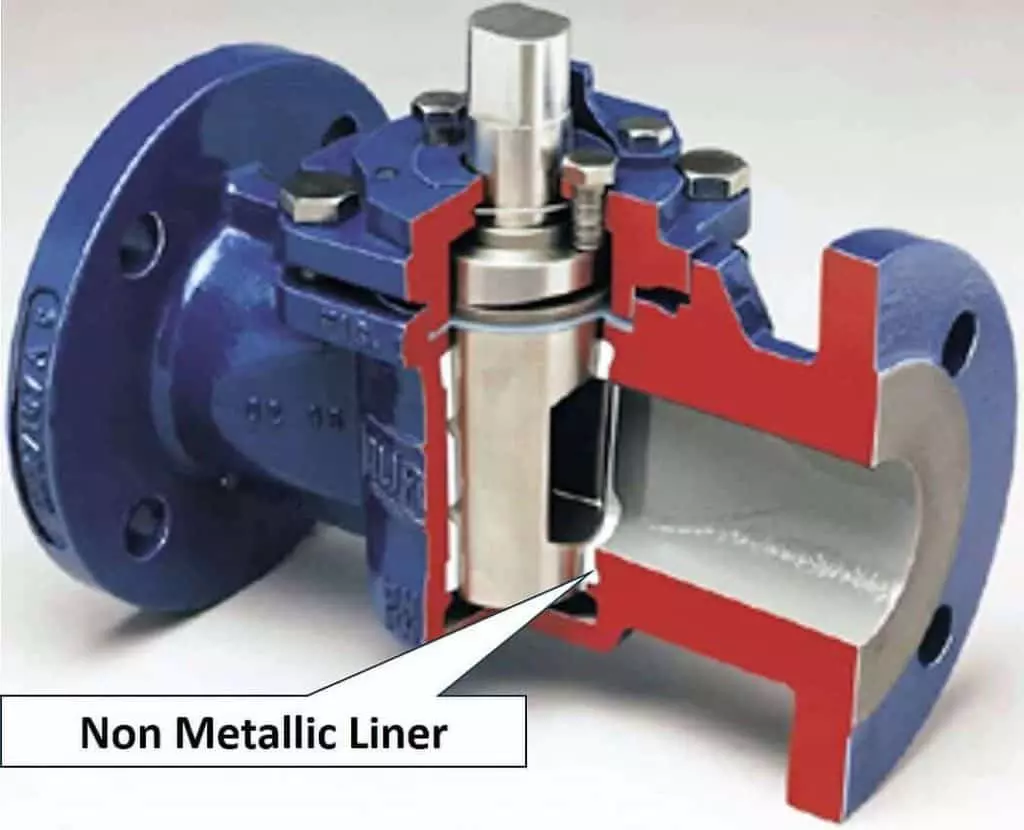

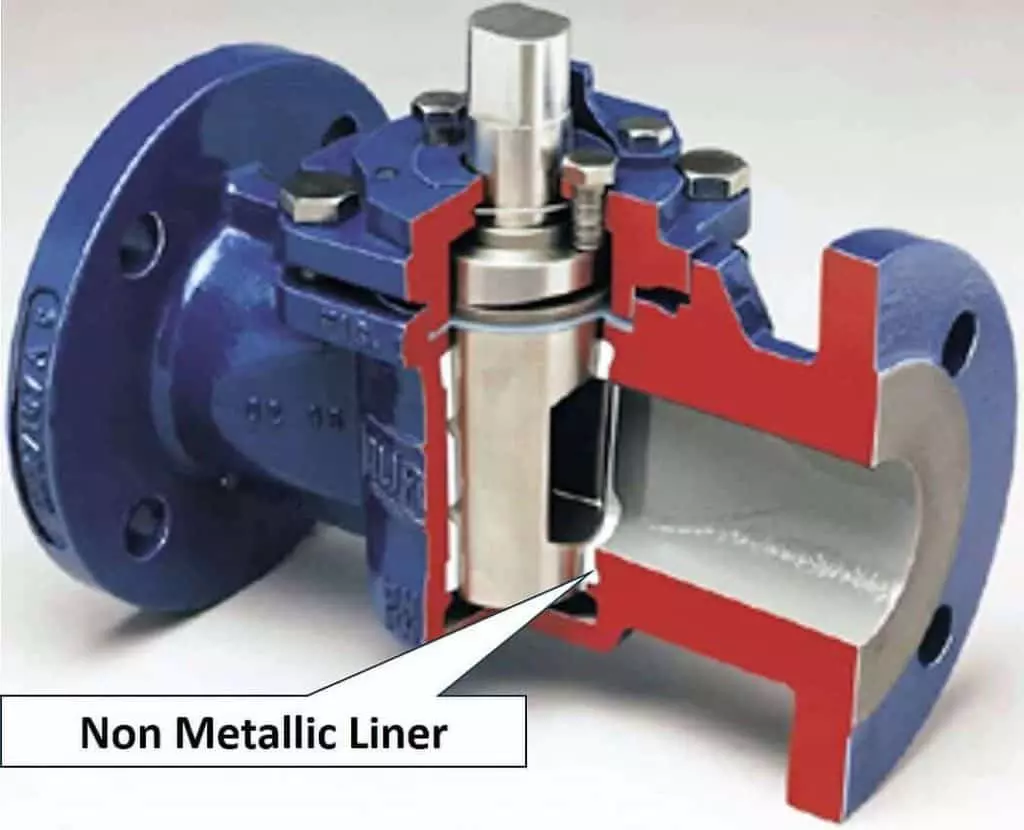

Non-lubricated Plug Valves

These plug valves uses nonmetallic elastomeric sleeves or liners. These sleeves are installed in the valve body cavity. The polished tapered plug serves as a wedge to press the sleeve onto the valve body.

This nonmetallic sleeve reduces the friction between the plug and the valve body. Non-lubricated plug valves require minimal maintenance. Due to nonmetallic valve seats, these valves are not used in high temperature environments.

Both lubricated and non-lubricated plug valves can provide bubble-tight shutoff and are compact in size.

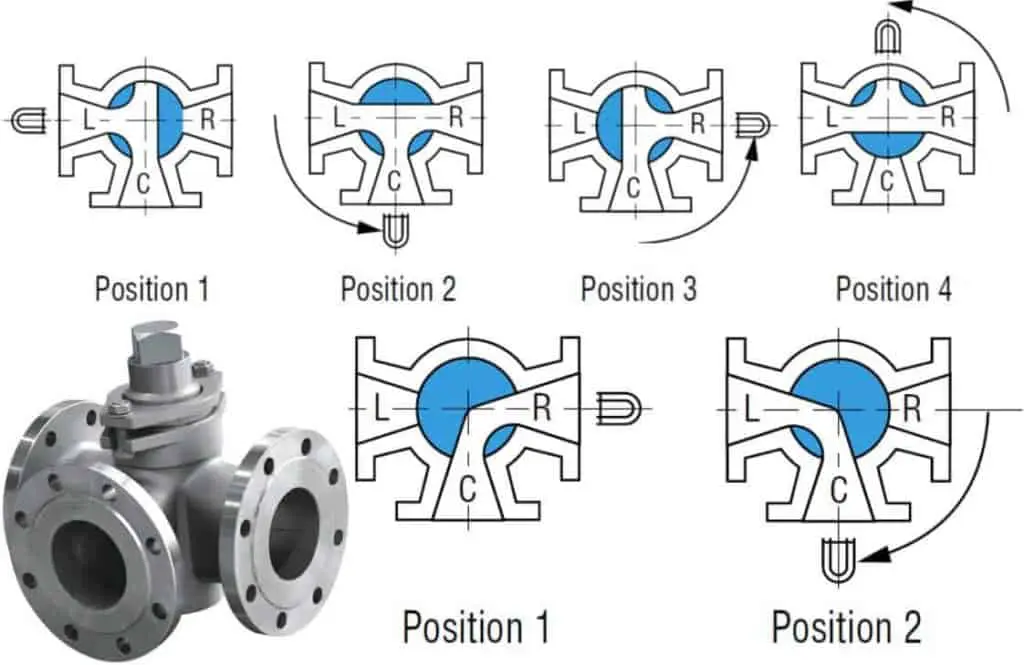

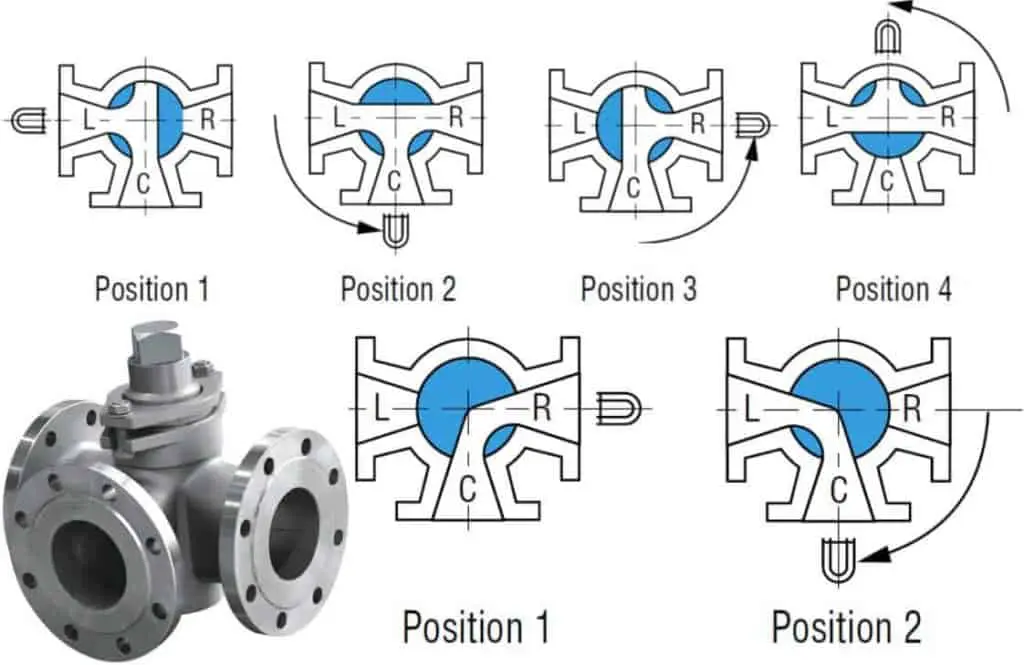

Multi-Port Plug Valves

Here you can see the three-way multi-port plug valve. The upper figure shows a 3-way 3-port design and the lower figure shows a 3-way 2-port design.

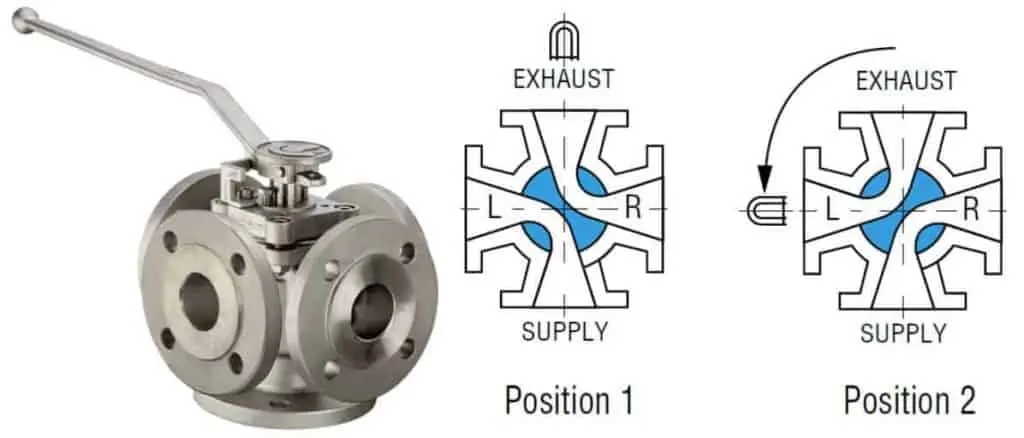

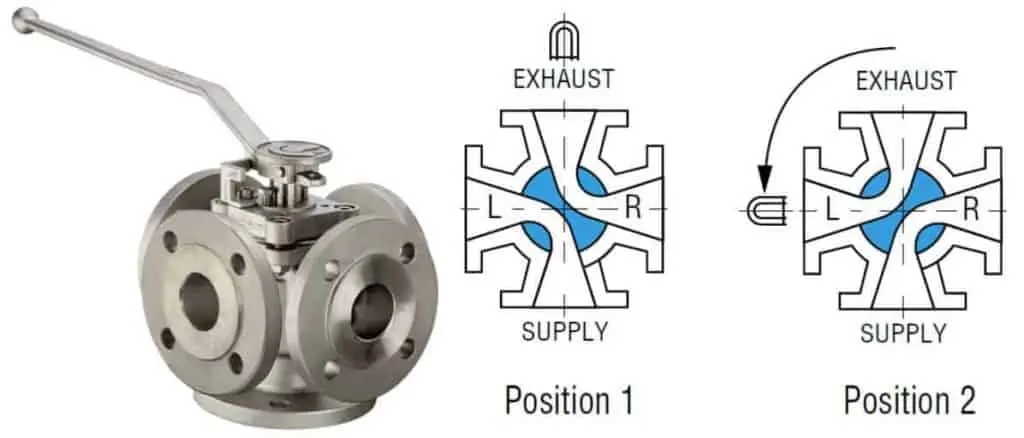

This is 4-way design.

Multi-port valves are used for transfer lines and diversion services. A single multi-port valve can replace three or four gate valves or other types of globe valves. However, sometimes the multi-port valve cannot entirely close the flow. For correct operation, special care should be taken when specifying a particular port arrangement.

Lubricated Plug Valve

The plug in a lubricated plug valve has a cavity in the middle along its axis. You can see this in the image. The lubricant chamber at the bottom and the sealant injection device at the top ensure the supply of lubricant.

In case the sealant is injected into the cavity, a check valve is below the injection fitting to prevent the sealant from flowing in the opposite direction.

The plug surface is continuously lubricated by the sealant, which enters the lubricant groove on the plug surface from the center cavity through radial holes. Why do we need all this? Many plug valves are of metal construction.

The narrow gap around the plug may cause leakage. If the gap is further reduced, friction will increase and the plug may become stuck in the valve body.

Lubricant reduces the force required to open or close the valve and allows the plug to move smoothly. Lubricants also prevent plug corrosion.

Lubricant materials must be compatible with pipeline fluids. They should not be dissolved or washed away by flow media. Otherwise, they may contaminate the fluid and damage the seal between the plug and the valve body, causing leakage. In addition, the sealant used must be able to resist the temperature of flow media.

The lubricated plug valve has a large size range and is suitable for working in high pressure and high temperature environment. These valves are less worn and have better corrosion resistance in certain service environments.

Non-lubricated Plug Valves

These plug valves uses nonmetallic elastomeric sleeves or liners. These sleeves are installed in the valve body cavity. The polished tapered plug serves as a wedge to press the sleeve onto the valve body.

This nonmetallic sleeve reduces the friction between the plug and the valve body. Non-lubricated plug valves require minimal maintenance. Due to nonmetallic valve seats, these valves are not used in high temperature environments.

Both lubricated and non-lubricated plug valves can provide bubble-tight shutoff and are compact in size.

Multi-Port Plug Valves

Here you can see the three-way multi-port plug valve. The upper figure shows a 3-way 3-port design and the lower figure shows a 3-way 2-port design.

This is 4-way design.

Multi-port valves are used for transfer lines and diversion services. A single multi-port valve can replace three or four gate valves or other types of globe valves. However, sometimes the multi-port valve cannot entirely close the flow. For correct operation, special care should be taken when specifying a particular port arrangement.