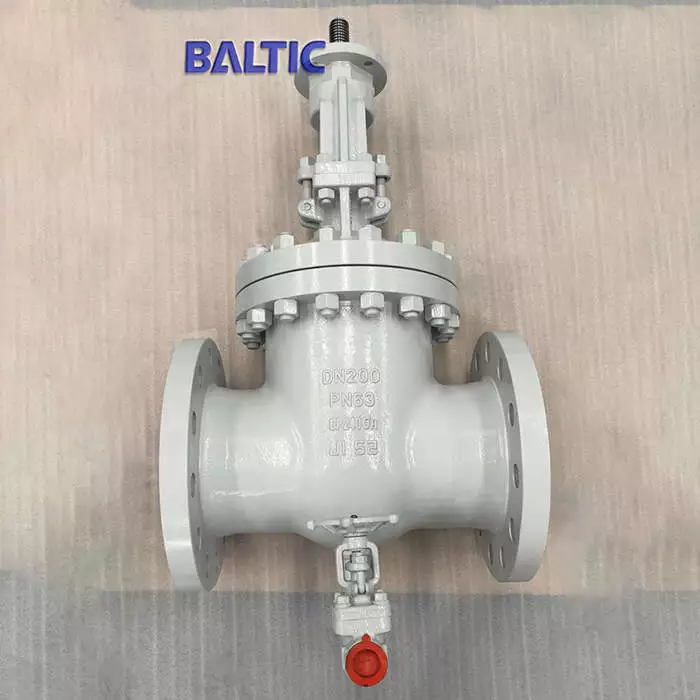

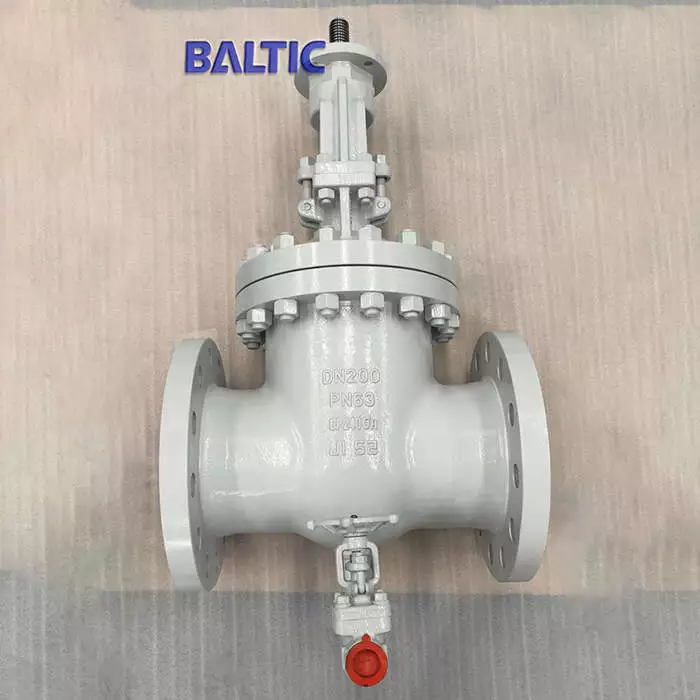

Special Design: Gate Valves with Drain Valves

We produced some gate valves with drain valves at the lower part of the body for tightness control for one of the European clients. The gate valves arrived at the client's warehouse last month by train. To protect our client's privacy, we have removed the logo on the valve body.

Product description Part A:

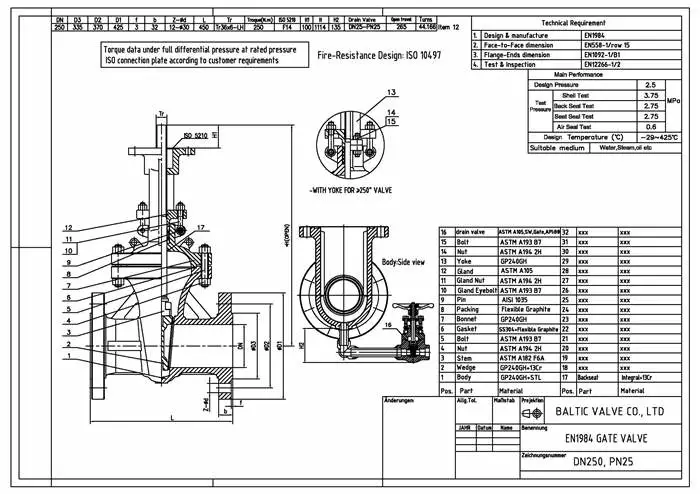

EN1984 Gate valve

BB with eye for handle, OS&Y, BG, Rising stem, Backseat, Flexible wedge,

All the gate valve with a drain valve at the lower part of the body used for tightness control, Fire-resistance design as per ISO 10497

***Body/Bonnet/Wedge: GP240GH (1.0619)

***Body seat: STL overlay

***Stem: min. 13%Cr

***Face to Face: EN558-1/row 26 - PN63

***Ends Connection: EN1092-1/B2

Butt weld ends acc.to EN 12627

Item 1) 13Qty DN250 - PN63 Bare stem with ISO top flange 5210 F14

FLG: EN1092-1/B2

Item 2) 2Qty DN250 - PN63 Bare stem with ISO top flange 5210 F14

Butt weld: EN 12627

Item 3) 2Qty DN250 - PN25 Bare stem with ISO top flange 5210 F14

FLG: EN1092-1/B2

Item 4) 4Qty DN200 - PN63 Bare stem with ISO top flange 5210 F14

FLG: EN1092-1/B2

Corrosion protection:

External coating system service temp. -30°C to +120°C

Corrosivity category C5-M acc. to ISO 12944-5:

- Surface preparation Sa 2½ acc. to ISO 8501-1

- First layer min. 75µm Spray painting Intergard 251

- Second layer min. 100µm Spray painting Intergard 475HS

- Third layer min. 65µm Spray painting Intergard 990

Total film thickness min. 240µm, RAL 7001 (silver grey)

Warranty period:

5 years/expected service life more than 15 years

If you are interested in gate valves with big sizes, pls freely contact us via email: [email protected]

Kindly, please find the attached GA drawings and valve pictures.

BALTIC VALVE CO., LTD

DATED Oct. 25, 2021

Product description Part A:

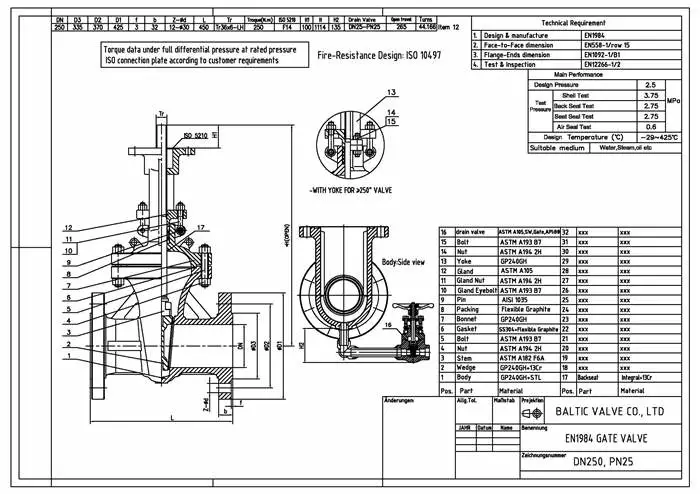

EN1984 Gate valve

BB with eye for handle, OS&Y, BG, Rising stem, Backseat, Flexible wedge,

All the gate valve with a drain valve at the lower part of the body used for tightness control, Fire-resistance design as per ISO 10497

***Body/Bonnet/Wedge: GP240GH (1.0619)

***Body seat: STL overlay

***Stem: min. 13%Cr

***Face to Face: EN558-1/row 26 - PN63

***Ends Connection: EN1092-1/B2

Butt weld ends acc.to EN 12627

Item 1) 13Qty DN250 - PN63 Bare stem with ISO top flange 5210 F14

FLG: EN1092-1/B2

Item 2) 2Qty DN250 - PN63 Bare stem with ISO top flange 5210 F14

Butt weld: EN 12627

Item 3) 2Qty DN250 - PN25 Bare stem with ISO top flange 5210 F14

FLG: EN1092-1/B2

Item 4) 4Qty DN200 - PN63 Bare stem with ISO top flange 5210 F14

FLG: EN1092-1/B2

Corrosion protection:

External coating system service temp. -30°C to +120°C

Corrosivity category C5-M acc. to ISO 12944-5:

- Surface preparation Sa 2½ acc. to ISO 8501-1

- First layer min. 75µm Spray painting Intergard 251

- Second layer min. 100µm Spray painting Intergard 475HS

- Third layer min. 65µm Spray painting Intergard 990

Total film thickness min. 240µm, RAL 7001 (silver grey)

Warranty period:

5 years/expected service life more than 15 years

If you are interested in gate valves with big sizes, pls freely contact us via email: [email protected]

Kindly, please find the attached GA drawings and valve pictures.

BALTIC VALVE CO., LTD

DATED Oct. 25, 2021