Metal Seated Ball Valves in Offshore Platforms (Part Two)

2. Technical requirements for metal seated wear-resistant ball valves in marine environments

2.1 Ultra-high wear resistance

Ball valves must be wear-resistant due to the effects of high temperatures and constant motion friction. The ball and valve seat sealing surfaces of this metal seated wear-resistant ball valve are sprayed with WC (tungsten carbide). The surface hardness of the coating is not less than 60HRC and 55HRC. The effective coating thickness after finishing is not less than 0.2mm. The sealing surface is in accordance with ASME B16.34—2017 "Valves with flange threads and welded connections" 100% PT (Penetrant Testing). This allows the metal seated ball valve to have high wear resistance and extend its service life.

2.2 Super corrosion resistance

The pressure-bearing parts of all wear-resistant metal seated ball valves are made by forging due to the strong corrosiveness of the marine environment. The body and bonnet of the valve with pressure not less than 900LB should be 100% tested by UT (Ultrasonic Testing, ultrasonic) in accordance with ASME B16.34-2017 to ensure the quality of valve forgings. For pressure-bearing parts in contact with the medium, the corrosion allowance of the medium on the pressure-bearing parts should be fully considered, and a corrosion allowance of not less than 3 mm should be added according to the ASME B16.34-2017 standard.

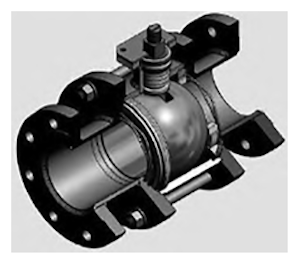

Figure 4 Sealing pairs of metal seated ball valves

2.3 Designing the sealing

The leakage level of the ball valve complies with the CL V level leakage requirements of ANSIB16-104/FCI70-2 "Control of Leakages of Valve Seats", ensuring zero leakage in both directions of the ball valve during the extraction, processing and transportation of offshore oil.

2.4 Double sealing of valve seats

The valve should be a two-way sealing type: for floating ball valves, either end as the upstream can ensure reliable sealing of the downstream; for trunnion ball valves, double block and bleed (DBB) should be provided, and a valve seat self-relieving; the pressure of the middle cavity does not exceed 1.33 times the rated pressure.

2.5 The structure of valve seats

The valve seat must be designed with a scraper, which can automatically remove solid particles and coking materials adhered to the surface of the ball to prevent solid particles and powder from being brought into the sealing surface between the ball and the valve seat, damaging the sealing pair. A disc spring should be adopted for the valve seat’s pre-tightening force. The valve seat must have an anti-dust function to prevent dust particles from entering the spring groove of the valve seat.

2.6 Surface roughness

The surface roughness Ra of the valve stem reaches 0.8 or higher, and the minimum yield point is located outside the pressure boundary. The valve stem material should be made of materials with high strength and hardness.

2.7 Fire resistance

The design and manufacturing requirements of the valve should consider the characteristics of the process medium and the operating temperature. The valve should comply with the fire test requirements of API 607-2016 "Valve Fire Tests" and API 6FA-2018 "Fire Test Standard of Valves".

3. Processing technology for the sealing surface of metal seated wear-resistant ball valves used in marine environments

3.1 Hardening of sealing surfaces

Different from soft seated ball core hardening, surface coating technology, cladding (spray) welding technology, and plasma nitriding technology can be used. These three sealing surface treatment methods are generally used in clean medium conditions such as refined oil, natural gas, low-temperature steam, and water. However, special media used in the petrochemical industry under harsh working conditions, such as two-phase flow or three-phase flow, have proven to have a very short service life. It is very critical to choose wear-resistant and corrosion-resistant sealing surface hardening technology, especially in coal chemical industry, polycrystalline silicon, crude oil processing with large sand content and other working conditions. In recent years, cermet coatings obtained through thermal spraying technology have been successfully promoted and applied at home and abroad. Among many spray materials, coatings based on WC have excellent performance in wear resistance, erosion resistance and dry sliding resistance. The performance is outstanding and suitable for the above-mentioned harsh working conditions. Coatings that often use WC as a base include WC12/Co, WC17/Co, WC20/Co, WC86/Co10Cr4, WC17/Ni and WC50/NiCrBSi.

Figure 5 Sealing rings of metal seated ball valves

3.2 Coatings

Supersonic flame spraying technology has the characteristics of fast particle flight speed in the deposition process and low spraying temperature. The advantages of this technology are that it ensures the decomposition of WC and controls the oxide content, making the coating structure more dense, and having less harmful phases or structures affecting the coating performance, more wear-resistant and erosion-resistant coatings. While determining the hardening process of the sealing surface of the wear-resistant ball valve, the spraying process parameters should be optimized and improved based on a large number of experiments to solve the problem that causes the coating to crack easily, that is, the residual stress of the coating should be controlled in a compressive stress state. At the same time, the particle size of the spray powder must be strictly controlled, and a certain proportion of high-temperature resistant lubricant must be added to the coating to better prepare a wear-resistant and corrosion-resistant coating with excellent performance in all aspects and reduce the friction coefficient of the sealing surface, thereby reducing the valve’s operating torque.

4. Conclusion

As China increasingly intensifies its efforts to control marine environmental pollution, the problem of leakage prevention is becoming increasingly severe in the process of offshore oil exploration and transportation; the corrosion rate of the marine environment is much greater than that of land. The anti-corrosion of its engineering equipment and pipeline systems is even more important. Seabed oil not only contains a large amount of organic matter and chemical elements, but also has a sand content that cannot be underestimated. Therefore, for valves frequently used on pipelines in offshore oil projects, high requirements such as high-temperature resistance, high-pressure resistance, wear resistance, corrosion resistance, scouring resistance and zero leakage are put forward.

Metal seated ball valves can well meet the above harsh working conditions, but there are two expectations for their use in the marine environment: First, metal seated wear-resistant ball valves have been widely used in the coal chemical industry on land, and combined with consideration of corrosiveness, marine engineering projects can use more metal seated wear-resistant ball valves. Second, it is hoped that more marine projects will give priority to Chinese valves when using metal seated ball valves, providing conditions for the advancement of valve technology in China.

2.1 Ultra-high wear resistance

Ball valves must be wear-resistant due to the effects of high temperatures and constant motion friction. The ball and valve seat sealing surfaces of this metal seated wear-resistant ball valve are sprayed with WC (tungsten carbide). The surface hardness of the coating is not less than 60HRC and 55HRC. The effective coating thickness after finishing is not less than 0.2mm. The sealing surface is in accordance with ASME B16.34—2017 "Valves with flange threads and welded connections" 100% PT (Penetrant Testing). This allows the metal seated ball valve to have high wear resistance and extend its service life.

2.2 Super corrosion resistance

The pressure-bearing parts of all wear-resistant metal seated ball valves are made by forging due to the strong corrosiveness of the marine environment. The body and bonnet of the valve with pressure not less than 900LB should be 100% tested by UT (Ultrasonic Testing, ultrasonic) in accordance with ASME B16.34-2017 to ensure the quality of valve forgings. For pressure-bearing parts in contact with the medium, the corrosion allowance of the medium on the pressure-bearing parts should be fully considered, and a corrosion allowance of not less than 3 mm should be added according to the ASME B16.34-2017 standard.

Figure 4 Sealing pairs of metal seated ball valves

2.3 Designing the sealing

The leakage level of the ball valve complies with the CL V level leakage requirements of ANSIB16-104/FCI70-2 "Control of Leakages of Valve Seats", ensuring zero leakage in both directions of the ball valve during the extraction, processing and transportation of offshore oil.

2.4 Double sealing of valve seats

The valve should be a two-way sealing type: for floating ball valves, either end as the upstream can ensure reliable sealing of the downstream; for trunnion ball valves, double block and bleed (DBB) should be provided, and a valve seat self-relieving; the pressure of the middle cavity does not exceed 1.33 times the rated pressure.

2.5 The structure of valve seats

The valve seat must be designed with a scraper, which can automatically remove solid particles and coking materials adhered to the surface of the ball to prevent solid particles and powder from being brought into the sealing surface between the ball and the valve seat, damaging the sealing pair. A disc spring should be adopted for the valve seat’s pre-tightening force. The valve seat must have an anti-dust function to prevent dust particles from entering the spring groove of the valve seat.

2.6 Surface roughness

The surface roughness Ra of the valve stem reaches 0.8 or higher, and the minimum yield point is located outside the pressure boundary. The valve stem material should be made of materials with high strength and hardness.

2.7 Fire resistance

The design and manufacturing requirements of the valve should consider the characteristics of the process medium and the operating temperature. The valve should comply with the fire test requirements of API 607-2016 "Valve Fire Tests" and API 6FA-2018 "Fire Test Standard of Valves".

3. Processing technology for the sealing surface of metal seated wear-resistant ball valves used in marine environments

3.1 Hardening of sealing surfaces

Different from soft seated ball core hardening, surface coating technology, cladding (spray) welding technology, and plasma nitriding technology can be used. These three sealing surface treatment methods are generally used in clean medium conditions such as refined oil, natural gas, low-temperature steam, and water. However, special media used in the petrochemical industry under harsh working conditions, such as two-phase flow or three-phase flow, have proven to have a very short service life. It is very critical to choose wear-resistant and corrosion-resistant sealing surface hardening technology, especially in coal chemical industry, polycrystalline silicon, crude oil processing with large sand content and other working conditions. In recent years, cermet coatings obtained through thermal spraying technology have been successfully promoted and applied at home and abroad. Among many spray materials, coatings based on WC have excellent performance in wear resistance, erosion resistance and dry sliding resistance. The performance is outstanding and suitable for the above-mentioned harsh working conditions. Coatings that often use WC as a base include WC12/Co, WC17/Co, WC20/Co, WC86/Co10Cr4, WC17/Ni and WC50/NiCrBSi.

Figure 5 Sealing rings of metal seated ball valves

3.2 Coatings

Supersonic flame spraying technology has the characteristics of fast particle flight speed in the deposition process and low spraying temperature. The advantages of this technology are that it ensures the decomposition of WC and controls the oxide content, making the coating structure more dense, and having less harmful phases or structures affecting the coating performance, more wear-resistant and erosion-resistant coatings. While determining the hardening process of the sealing surface of the wear-resistant ball valve, the spraying process parameters should be optimized and improved based on a large number of experiments to solve the problem that causes the coating to crack easily, that is, the residual stress of the coating should be controlled in a compressive stress state. At the same time, the particle size of the spray powder must be strictly controlled, and a certain proportion of high-temperature resistant lubricant must be added to the coating to better prepare a wear-resistant and corrosion-resistant coating with excellent performance in all aspects and reduce the friction coefficient of the sealing surface, thereby reducing the valve’s operating torque.

4. Conclusion

As China increasingly intensifies its efforts to control marine environmental pollution, the problem of leakage prevention is becoming increasingly severe in the process of offshore oil exploration and transportation; the corrosion rate of the marine environment is much greater than that of land. The anti-corrosion of its engineering equipment and pipeline systems is even more important. Seabed oil not only contains a large amount of organic matter and chemical elements, but also has a sand content that cannot be underestimated. Therefore, for valves frequently used on pipelines in offshore oil projects, high requirements such as high-temperature resistance, high-pressure resistance, wear resistance, corrosion resistance, scouring resistance and zero leakage are put forward.

Metal seated ball valves can well meet the above harsh working conditions, but there are two expectations for their use in the marine environment: First, metal seated wear-resistant ball valves have been widely used in the coal chemical industry on land, and combined with consideration of corrosiveness, marine engineering projects can use more metal seated wear-resistant ball valves. Second, it is hoped that more marine projects will give priority to Chinese valves when using metal seated ball valves, providing conditions for the advancement of valve technology in China.

Previous: Metal Seated Ball Valves in Offshore Platforms (Part One)

Next: Online Detection for Valves in Petrochemical Plants

Next: Online Detection for Valves in Petrochemical Plants