Internal Leakages of Ball Valves in Gas Transmission Stations

Ball valves are an essential component in gas transmission stations, and their importance cannot be overstated. These valves play a crucial role in regulating the flow of gas, ensuring safety, and preventing potential disasters. Firstly, ball valves offer superior control over the flow of gas. Their design allows for quick and precise adjustments, enabling operators to regulate the pressure and volume of gas passing through the pipelines. This level of control is vital in maintaining a stable and efficient gas transmission system. Secondly, ball valves provide enhanced safety measures. In case of emergencies or unforeseen circumstances such as leaks or ruptures, these valves can be quickly shut off to isolate affected sections. This prevents further damage and minimizes risks to personnel working at the station or nearby communities. Moreover, ball valves are known for their durability and reliability. Gas transmission stations operate under high-pressure conditions that require robust equipment capable of withstanding extreme conditions. Ball valves are designed to handle such pressures without compromising performance or integrity. Lastly, investing in high-quality ball valves can result in long-term cost savings. By choosing reliable products upfront, maintenance costs are reduced as these valves require minimal servicing over time.

In conclusion, ball valves are indispensable components in gas transmission stations due to their ability to regulate flow accurately, enhance safety measures, provide durability under high-pressure conditions, and offer long-term cost savings. Gas transmission stations prioritize the use of quality ball valves to ensure efficient operations while safeguarding lives and infrastructure from potential disasters.

The internal leakage of ball valves in gas transmission stations is a critical issue that needs immediate attention. These valves are responsible for controlling the flow of gas and ensuring the safety and efficiency of the entire transmission system. However, when internal leakage occurs, it can lead to significant problems such as loss of pressure, increased energy consumption, and even potential safety hazards.

Firstly, internal leakage results in a loss of pressure within the transmission system. This not only affects the overall efficiency but also leads to increased energy consumption as more gas is required to compensate for the lost pressure. This inefficiency can have severe financial implications for gas transmission companies and ultimately impact consumers who may face higher prices.

Moreover, internal leakage poses serious safety risks. Gas leaks can result in explosions or fires if left undetected or unaddressed. The consequences could be catastrophic not only for workers at these stations but also for nearby communities.

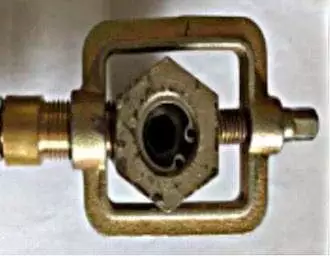

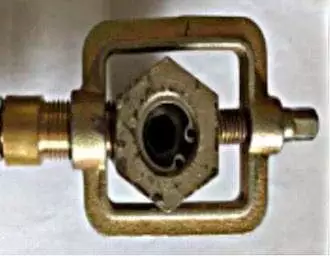

For ball valves with drain nozzles or vent ports in valve chambers, special fixtures or interfaces are designed to connect to the drain nozzles or vent ports (as shown in Figure 1), so that the gas discharged from the drain nozzles or vent ports can be drawn; and then connected to the flow meter through the pipeline to realize the measurement of the gas in the valve and the accurate measurement of the leakage amount of the valve.

Figure 1 Special fixtures for drain nozzles of valves

The steps to measure the internal leakage of the valve through the valve drain nozzle are as follows:

(1) Close the ball valve to be tested for internal leakages, and do not discharge the gas in the upstream and downstream process systems of the valve.

(2) After the valve is closed, manually open the drain nozzle of the valve cavity to discharge the sewage until the sewage in the valve cavity is discharged.

(3) Continue to discharge the high-pressure gas in the valve chamber after the dirt is discharged. If the gas in the valve chamber cannot be discharged all the time or the gas is released after a short period of pressure after the discharge, it means that the valve internally leakages, and the amount of internal leakages of the valve needs to be measured.

(4) Close the drain nozzle, and install the special fixture and metering system for the sewage nozzle.

(5) After the installation is completed, slowly open the sewage nozzle, so that the gas in the valve cavity enters the flowmeter through the drain nozzle; the flowmeter measures the inflowing gas, and controls the opening of the sewage nozzle so that the gas flow does not exceed the flow measurement range. If the gas flow tends to exceed the range of the flowmeter, a flowmeter with a greater range should be replaced.

(6) Record the data after the flow reading of the flow meter is stable or the drain nozzle is fully opened. This reading is the total internal leakage rate of the upstream and downstream valve seats of the valve.

(7) Close the drain nozzle of the valve chamber and disassemble the flowmeter.

(8) Open the ball valve and resume the process flow.

To address this issue effectively, regular maintenance and inspection protocols must be implemented. Investing in state-of-the-art technology that allows for real-time monitoring and detection of leaks is crucial. Additionally, training programs should be provided to ensure that personnel are equipped with the necessary skills to identify and repair any leakages promptly.

In conclusion, ball valves are indispensable components in gas transmission stations due to their ability to regulate flow accurately, enhance safety measures, provide durability under high-pressure conditions, and offer long-term cost savings. Gas transmission stations prioritize the use of quality ball valves to ensure efficient operations while safeguarding lives and infrastructure from potential disasters.

The internal leakage of ball valves in gas transmission stations is a critical issue that needs immediate attention. These valves are responsible for controlling the flow of gas and ensuring the safety and efficiency of the entire transmission system. However, when internal leakage occurs, it can lead to significant problems such as loss of pressure, increased energy consumption, and even potential safety hazards.

Firstly, internal leakage results in a loss of pressure within the transmission system. This not only affects the overall efficiency but also leads to increased energy consumption as more gas is required to compensate for the lost pressure. This inefficiency can have severe financial implications for gas transmission companies and ultimately impact consumers who may face higher prices.

Moreover, internal leakage poses serious safety risks. Gas leaks can result in explosions or fires if left undetected or unaddressed. The consequences could be catastrophic not only for workers at these stations but also for nearby communities.

For ball valves with drain nozzles or vent ports in valve chambers, special fixtures or interfaces are designed to connect to the drain nozzles or vent ports (as shown in Figure 1), so that the gas discharged from the drain nozzles or vent ports can be drawn; and then connected to the flow meter through the pipeline to realize the measurement of the gas in the valve and the accurate measurement of the leakage amount of the valve.

Figure 1 Special fixtures for drain nozzles of valves

The steps to measure the internal leakage of the valve through the valve drain nozzle are as follows:

(1) Close the ball valve to be tested for internal leakages, and do not discharge the gas in the upstream and downstream process systems of the valve.

(2) After the valve is closed, manually open the drain nozzle of the valve cavity to discharge the sewage until the sewage in the valve cavity is discharged.

(3) Continue to discharge the high-pressure gas in the valve chamber after the dirt is discharged. If the gas in the valve chamber cannot be discharged all the time or the gas is released after a short period of pressure after the discharge, it means that the valve internally leakages, and the amount of internal leakages of the valve needs to be measured.

(4) Close the drain nozzle, and install the special fixture and metering system for the sewage nozzle.

(5) After the installation is completed, slowly open the sewage nozzle, so that the gas in the valve cavity enters the flowmeter through the drain nozzle; the flowmeter measures the inflowing gas, and controls the opening of the sewage nozzle so that the gas flow does not exceed the flow measurement range. If the gas flow tends to exceed the range of the flowmeter, a flowmeter with a greater range should be replaced.

(6) Record the data after the flow reading of the flow meter is stable or the drain nozzle is fully opened. This reading is the total internal leakage rate of the upstream and downstream valve seats of the valve.

(7) Close the drain nozzle of the valve chamber and disassemble the flowmeter.

(8) Open the ball valve and resume the process flow.

To address this issue effectively, regular maintenance and inspection protocols must be implemented. Investing in state-of-the-art technology that allows for real-time monitoring and detection of leaks is crucial. Additionally, training programs should be provided to ensure that personnel are equipped with the necessary skills to identify and repair any leakages promptly.

Previous: Basic Design Requirements for Spent Fuel Reprocessing Process Valves

Next: Inspecting Internal Leakages of Buried Ball Valves

Next: Inspecting Internal Leakages of Buried Ball Valves