High-Performance Gate Valves for Demanding Applications

Baltic Valve Co., Ltd., renowned for its commitment to quality engineering solutions, announces the availability of specialized gate valves constructed from 1.4466 (AISI 310 MoLN) material, specifically designed to meet rigorous operational demands.

Key Specifications:

Material: 1.4466 (AISI 310 MoLN)

Medium and Design Conditions: Water (H2O), Ammonia (NH3), Carbon Dioxide (CO2) at temperatures up to +290°C and a maximum working pressure of 82 bar.

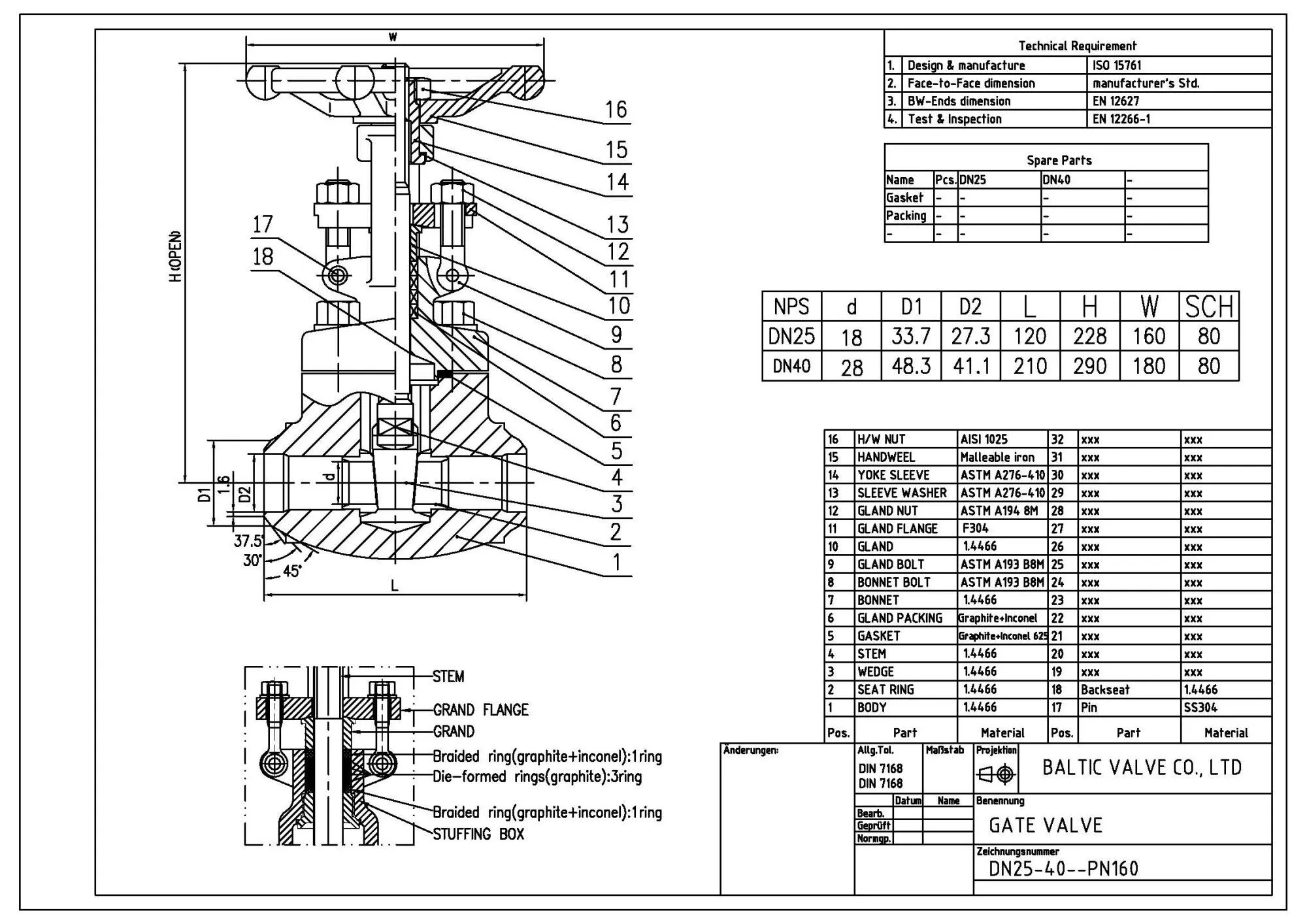

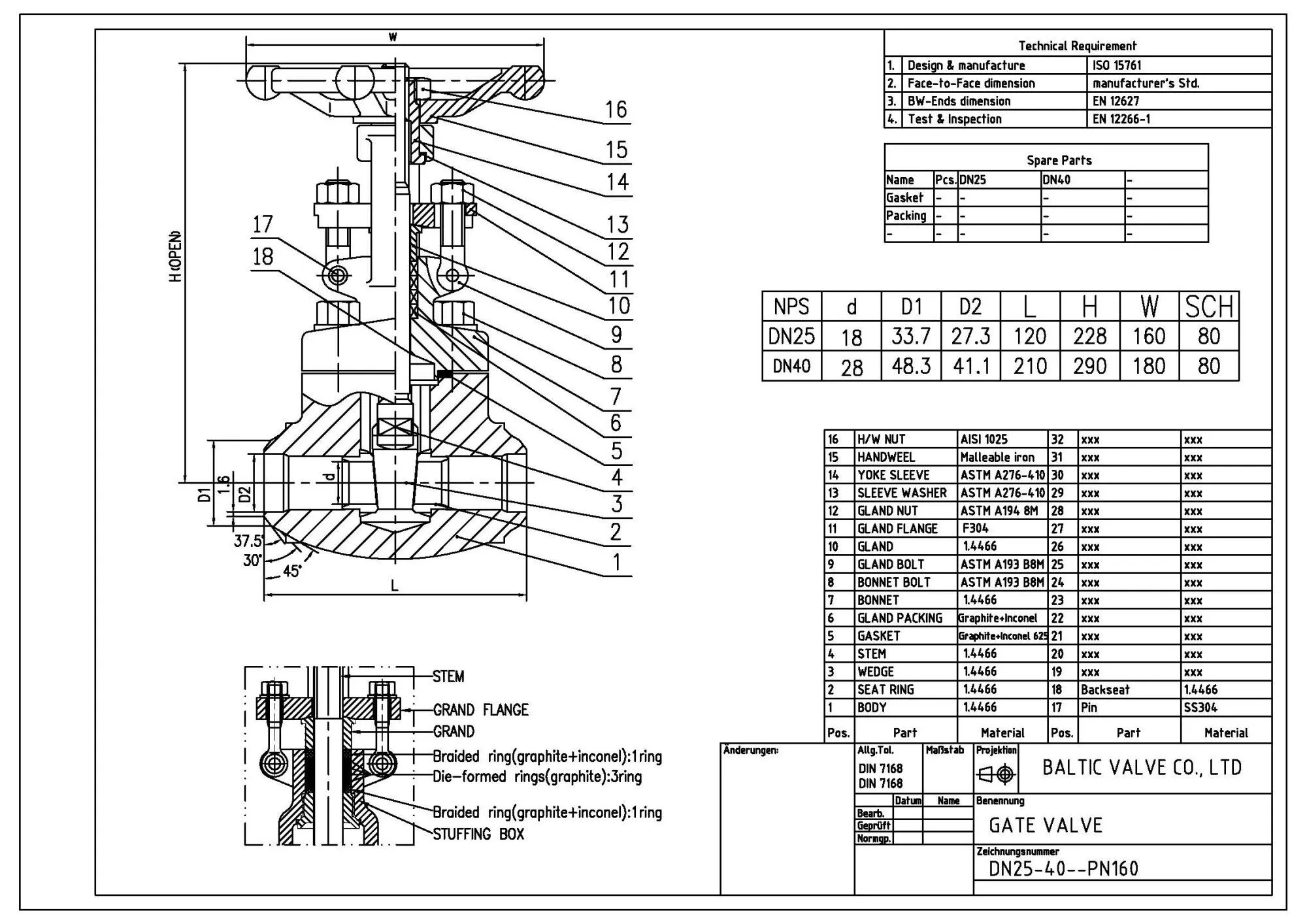

Product Description: Gate valve with hand wheel, Bolted bonnet, Rising stem, Outside screw and yoke, Backseat, Solid wedge.

Features:

Construction: Body, Bonnet, Wedge, Seat, and Stem all made from 1.4466 (AISI 310 MoLN) for exceptional durability and corrosion resistance.

Sealing: Gasket spiral wound with 1.4404 (316L) and Graphite, Stem packing with Graphite.

Fastening: Stud bolting ASTM A193 - B8M, Stud nut ASTM A194 - 8M.

Available Models:

Interested parties can contact BALTIC VALVE via email at [email protected] for more information and inquiries. Attached to this announcement are the GA drawings and valve pictures for further reference.

About Baltic Valve Co., Ltd:

Baltic Valve Co., Ltd. specializes in the manufacturing and supply of high-quality valves tailored to meet stringent industrial requirements. With a commitment to innovation and reliability, Baltic Valve continues to deliver excellence in valve solutions worldwide.

Date: June 14th, 2024

Key Specifications:

Material: 1.4466 (AISI 310 MoLN)

Medium and Design Conditions: Water (H2O), Ammonia (NH3), Carbon Dioxide (CO2) at temperatures up to +290°C and a maximum working pressure of 82 bar.

Product Description: Gate valve with hand wheel, Bolted bonnet, Rising stem, Outside screw and yoke, Backseat, Solid wedge.

Features:

Construction: Body, Bonnet, Wedge, Seat, and Stem all made from 1.4466 (AISI 310 MoLN) for exceptional durability and corrosion resistance.

Sealing: Gasket spiral wound with 1.4404 (316L) and Graphite, Stem packing with Graphite.

Fastening: Stud bolting ASTM A193 - B8M, Stud nut ASTM A194 - 8M.

Available Models:

Item 1) PN160 - DN40, Length 210mm, Butt weld ends as per EN 12627 (⌀ 48.3 x 3.6mm).

Item 2) PN160 - DN25, Length 120mm, Butt weld ends as per EN 12627 (⌀ 33.7 x 3.2mm).

Interested parties can contact BALTIC VALVE via email at [email protected] for more information and inquiries. Attached to this announcement are the GA drawings and valve pictures for further reference.

About Baltic Valve Co., Ltd:

Baltic Valve Co., Ltd. specializes in the manufacturing and supply of high-quality valves tailored to meet stringent industrial requirements. With a commitment to innovation and reliability, Baltic Valve continues to deliver excellence in valve solutions worldwide.

Date: June 14th, 2024

Previous: DIN / EN Gate Valve for Sea Water and Liquid Saline, Special Material

Next: Premium Super Duplex Steel ASTM A182 F51 Ball Valve Compatible with Limitorque Actuator

Next: Premium Super Duplex Steel ASTM A182 F51 Ball Valve Compatible with Limitorque Actuator