High-Performance Butterfly Valves for Seawater Applications

On this page

We have successfully delivered a set of large, high-performance butterfly valves to a major client in South America. As a leading Chinese manufacturer of industrial valves, Baltic Valve Co., Ltd. specializes in providing solutions designed for demanding seawater environments. These valves are a key component in the client's infrastructure, further solidifying Baltic Valve’s reputation for quality, reliability, and innovation.

Key Specifications Include:

Design Standard: API 609 for superior performance in extreme conditions.

Face-to-Face Dimension Standard: ASME B16.5.

Testing and Inspection: Conducted in accordance with API 598 with a tightness class A, ensuring zero leakage under stringent operating conditions.

These valves were designed to meet the unique challenges of seawater applications, making them a vital part of the client's project.

Baltic Valve Co., Ltd. has a long history of supplying high-performance valves for seawater applications, including desalination plants, offshore platforms, and other marine infrastructure. The delivery of these valves to a South American client further solidifies its position as a leader in the industry.

BALTIC VALVE CO., LTD

DATED Sep. 9th , 2024

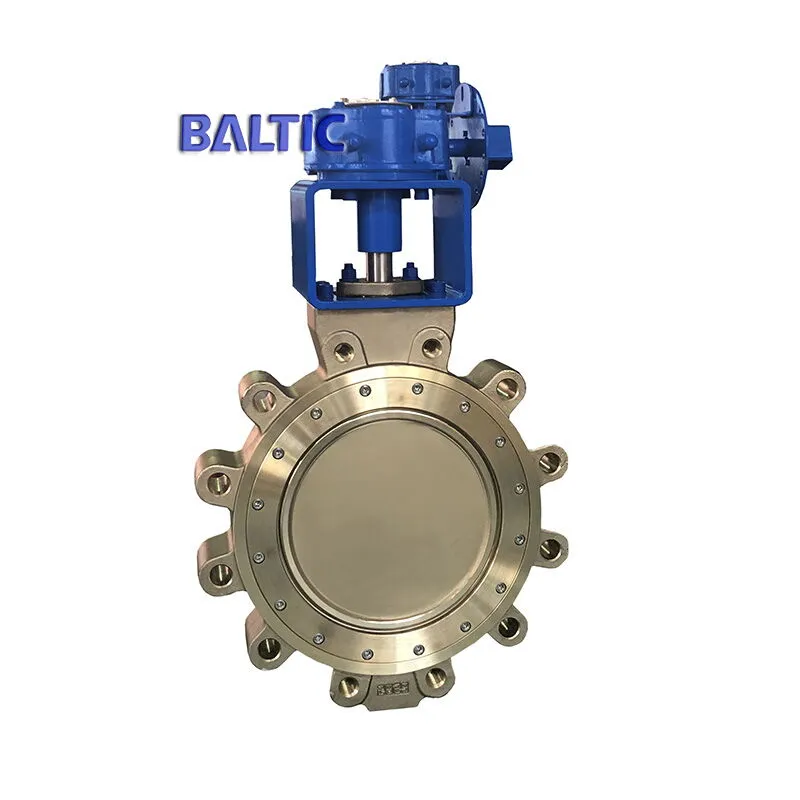

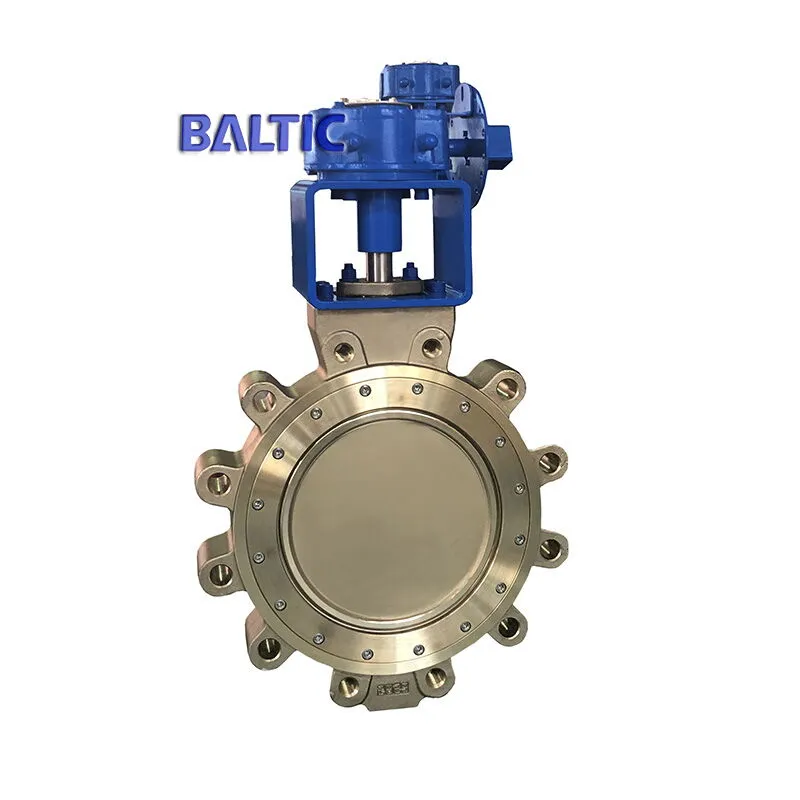

Overview of Delivered Products

The shipment included 10 units of high-performance lug-type butterfly valves, each with an 8-inch diameter and rated for ANSI Class 150. These valves feature double eccentricity, which ensures tight sealing and reduced friction during operation, leading to enhanced durability and reliability over extended use.Key Specifications Include:

Design Standard: API 609 for superior performance in extreme conditions.

Face-to-Face Dimension Standard: ASME B16.5.

Testing and Inspection: Conducted in accordance with API 598 with a tightness class A, ensuring zero leakage under stringent operating conditions.

These valves were designed to meet the unique challenges of seawater applications, making them a vital part of the client's project.

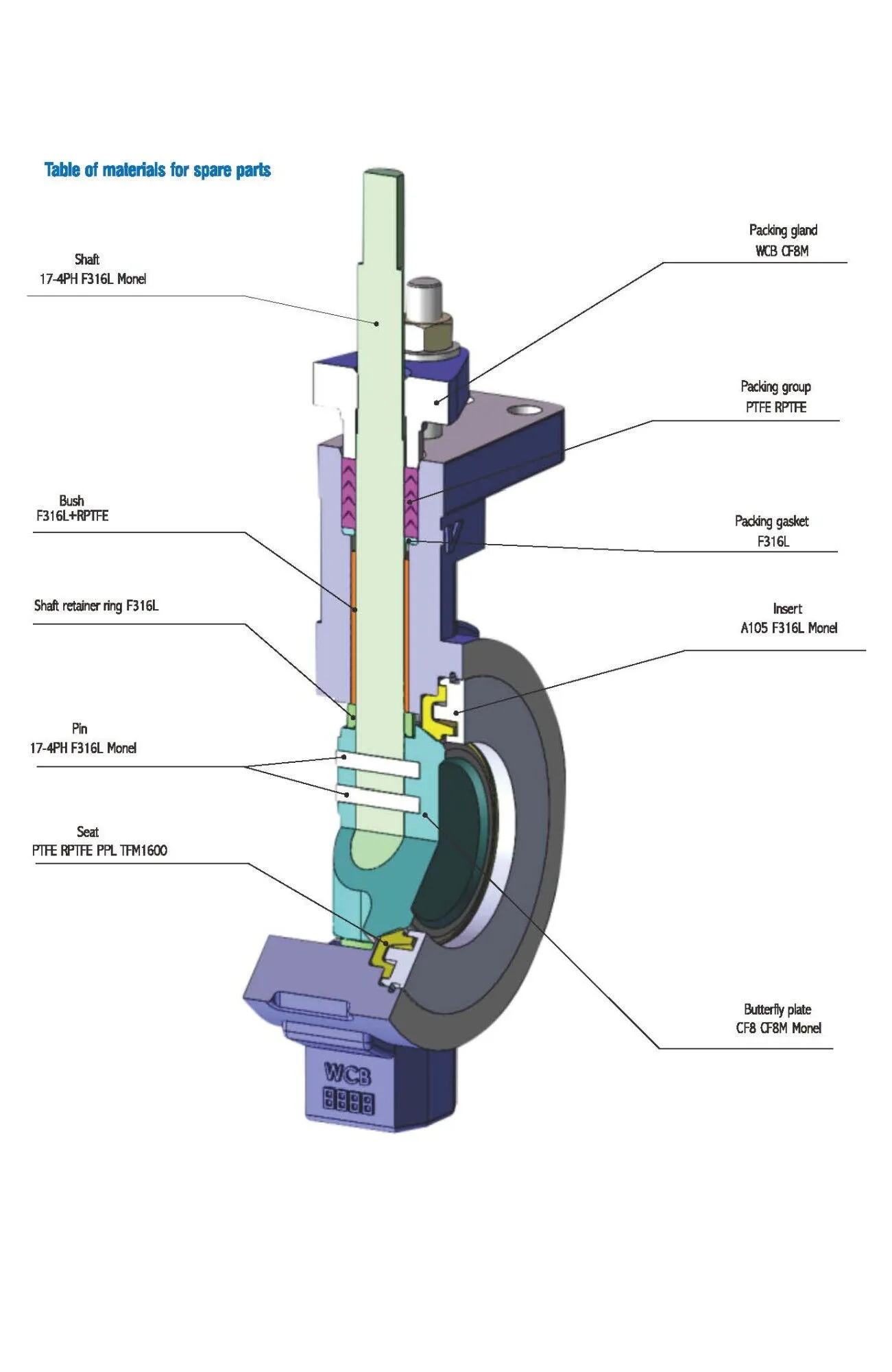

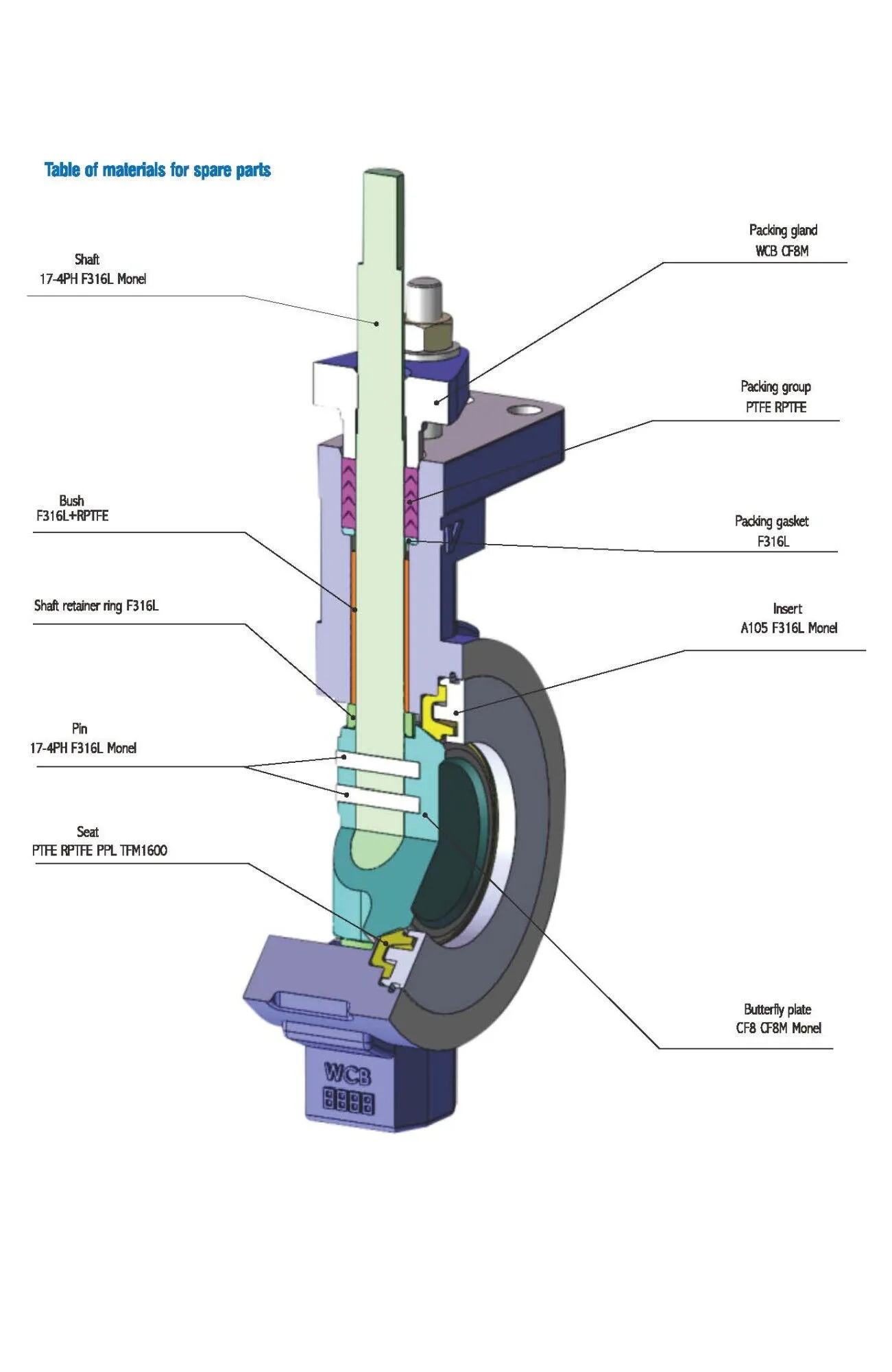

Premium Materials for Enhanced Durability

The valves feature ASTM B148 C95800 aluminum bronze for corrosion resistance, MONEL K500 stem for strength, and RPTFE seats for superior sealing. The stainless steel SS 316 gearbox bracket and anti-acid paint coating ensure added protection and longevity in harsh marine environments.Reliable Operation and User-Friendly Design

The valves are equipped with a manual gear operator and a handwheel, allowing for smooth and precise control over valve operation. Each valve also includes a position indicator, making it easy for operators to monitor the valve’s status at a glance. This user-friendly design ensures the valves can be operated and maintained with minimal effort, reducing downtime and operational costs for the end-user.Customized Solutions for Global Clients

Baltic Valve Co., Ltd. specializes in tailoring valve solutions to meet the specific needs of its clients. The company worked closely with its South American client to ensure the valves were manufactured to the exact specifications required for their application. This dedication to customization and high-quality engineering demonstrates Baltic Valve’s commitment to providing tailored solutions for industries facing complex challenges.Seawater Applications Demand High-Performance Solutions

Seawater environments pose unique challenges due to the corrosive properties of saltwater. Valves operating in these environments must resist corrosion, maintain a tight seal, and offer reliable performance over long periods of time. The aluminum bronze construction of the valves, combined with the MONEL K500 stem and RPTFE seat, ensures that these butterfly valves are more than capable of meeting these demands.Baltic Valve Co., Ltd. has a long history of supplying high-performance valves for seawater applications, including desalination plants, offshore platforms, and other marine infrastructure. The delivery of these valves to a South American client further solidifies its position as a leader in the industry.

Contact Baltic Valve Co., Ltd.

Baltic Valve Co., Ltd. offers tailored solutions for high-performance butterfly valves in seawater and demanding applications. For inquiries, email [email protected] for details and product information. Please find attached the GA drawings and pictures of the high-performance butterfly valves.

BALTIC VALVE CO., LTD

DATED Sep. 9th , 2024

Previous: Delivery of High-Performance Butterfly Valves to South America

Next: DIN Globe Valve PN40 Series Now Available in Stock

Next: DIN Globe Valve PN40 Series Now Available in Stock