Gate Valve Versus Globe Valve

1. Structure

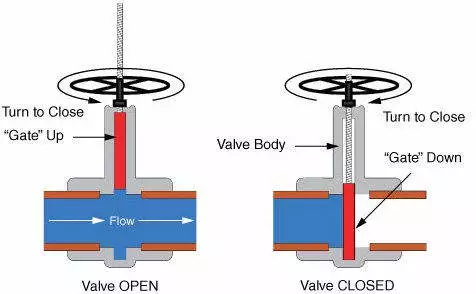

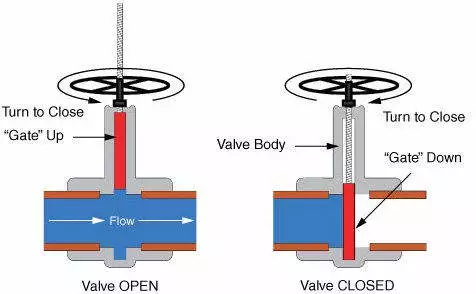

Gate valve is shorter and higher than globe valve, so it needs attention to install rising stem valve. In case of the limited space, people should note that what kind of valve is appropriate. Gate valve is able to close the sealing surface relied on medium pressure, thus it can achieve the effect of no leakage. When opening or closing valve, the spool and the sealing surface of seat will always rub each other, therefore, the sealing surface is easy to wear, when the gate valve is approaching to close, there will be a gap between the previous pressure and the later pressure, resulting in more severe abrasion.

2. Principle

The running way of hand wheel and stem is different. Globe valve belongs to rising stem type, its hand wheel does rotation and upward movement together with the stem. However, for the gate valve, its hand wheel does rotation while the stem dose upward movement. The flow flux is also different. Gate valve needs full opening or full close, but globe valve doesn’t need. Globe valve has prescriptive direction of inlet and outlet, but gate valve has no.

The flow path of gate valve is the same as straight pipe, just one more gate is set in the middle. If we

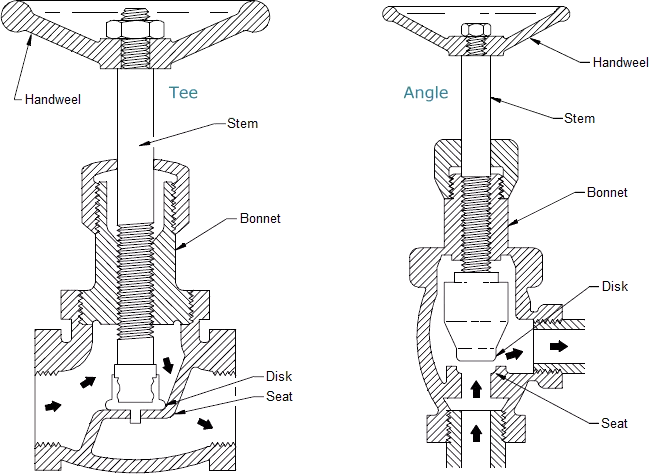

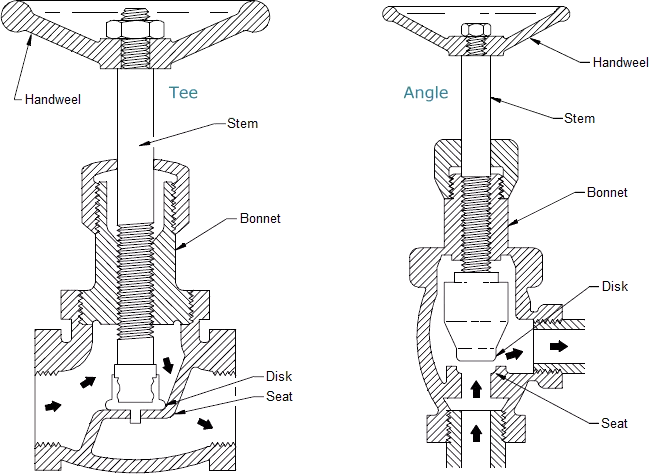

rise up the gate, the gate valve will be in full open. Unlike gate valve, the fluid will turn 180 degree in the valve. Usually, after the fluid flows into valve from one side, there will be a upflow by turning 90 degree, then, when the fluid contacts the top of valve body, it will flow out by turning 90 degree again. Its cover is set in the outlet of upflow.

3. Flow direction

Viewed from the out side, the flow path of globe valve is not in the same horizontal line, the fluid flows into the valve from lower inlet and flows out from higher position. While the flow path of gate valve is linear. The route of gate valve is longer than the globe valve's.

From the view of flow resistance, when valve is in the state of full open, the flow resistance of gate valve is smaller than that of globe valve. The flow resistance coefficient of common gate valve is 0.08 - 0.12. The medium can flow towards two directions. The flow resistance coefficient of common globe valve is 3-5 times than that of gate valve's. It needs forced seal. The spool of globe valve will contact the sealing surface only in the case of full close. Therefore, there is little abrasion.

4. Sealing surface

The sealing surface of globe valve is a trapezoidal profile of valve spool(depending on the shape of valve spool). Once the valve spool fell off, the valve is closed. The sealing of gate valve relies on the profile of valve spool and valve gate. Its sealing effect is inferior to globe valve. Unlike globe valve, the valve spool falling off is not equal to closing the valve.

5. Installation

Gate valve: The effects of two flow directions are the same.

Globe valve: There are two ways of installing globe valve. The first way is to let medium flow from down to up. The advantage of this way is that the disc has no pressure, which can not only prolong the service life of disc, but also is easy for replacing the disc. The disadvantage is that driving torque is twice as big as the second way. The stem is easy to bend because of big axial force. So this way is only suitable for small-diameter globe valve(less than DN50). The second way is to let medium flow from up to down, which is suitable for large-diameter valve(more than DN200). Usually, electric globe valve will be installed by this way. The disadvantage is just the opposite of the first way.

Gate valve is shorter and higher than globe valve, so it needs attention to install rising stem valve. In case of the limited space, people should note that what kind of valve is appropriate. Gate valve is able to close the sealing surface relied on medium pressure, thus it can achieve the effect of no leakage. When opening or closing valve, the spool and the sealing surface of seat will always rub each other, therefore, the sealing surface is easy to wear, when the gate valve is approaching to close, there will be a gap between the previous pressure and the later pressure, resulting in more severe abrasion.

2. Principle

The running way of hand wheel and stem is different. Globe valve belongs to rising stem type, its hand wheel does rotation and upward movement together with the stem. However, for the gate valve, its hand wheel does rotation while the stem dose upward movement. The flow flux is also different. Gate valve needs full opening or full close, but globe valve doesn’t need. Globe valve has prescriptive direction of inlet and outlet, but gate valve has no.

The flow path of gate valve is the same as straight pipe, just one more gate is set in the middle. If we

rise up the gate, the gate valve will be in full open. Unlike gate valve, the fluid will turn 180 degree in the valve. Usually, after the fluid flows into valve from one side, there will be a upflow by turning 90 degree, then, when the fluid contacts the top of valve body, it will flow out by turning 90 degree again. Its cover is set in the outlet of upflow.

3. Flow direction

Viewed from the out side, the flow path of globe valve is not in the same horizontal line, the fluid flows into the valve from lower inlet and flows out from higher position. While the flow path of gate valve is linear. The route of gate valve is longer than the globe valve's.

From the view of flow resistance, when valve is in the state of full open, the flow resistance of gate valve is smaller than that of globe valve. The flow resistance coefficient of common gate valve is 0.08 - 0.12. The medium can flow towards two directions. The flow resistance coefficient of common globe valve is 3-5 times than that of gate valve's. It needs forced seal. The spool of globe valve will contact the sealing surface only in the case of full close. Therefore, there is little abrasion.

4. Sealing surface

The sealing surface of globe valve is a trapezoidal profile of valve spool(depending on the shape of valve spool). Once the valve spool fell off, the valve is closed. The sealing of gate valve relies on the profile of valve spool and valve gate. Its sealing effect is inferior to globe valve. Unlike globe valve, the valve spool falling off is not equal to closing the valve.

5. Installation

Gate valve: The effects of two flow directions are the same.

Globe valve: There are two ways of installing globe valve. The first way is to let medium flow from down to up. The advantage of this way is that the disc has no pressure, which can not only prolong the service life of disc, but also is easy for replacing the disc. The disadvantage is that driving torque is twice as big as the second way. The stem is easy to bend because of big axial force. So this way is only suitable for small-diameter globe valve(less than DN50). The second way is to let medium flow from up to down, which is suitable for large-diameter valve(more than DN200). Usually, electric globe valve will be installed by this way. The disadvantage is just the opposite of the first way.