Fire Resistance Testing Equipment for Pipes and Valves

A valve is an important device on pressure pipelines and is widely used in various industries such as petrochemical, steel smelting, thermal power generation, nuclear power, water conservancy and hydropower industries. Fire resistance testing equipment and detection are discussed in this article.

Testing Equipment

According to the requirements of fire resistance test standards of the valve, a remotely controlled, safe, reliable and accurate measuring equipment was designed (Figure 1). The heat source for the fire resistance test of the valve uses liquefied natural gas. To ensure the safety of the test, a remote controller was developed. It was believed that the remote control system should send signals to the computer and realize the remote control to adjust the flame and test temperature. During the fire resistance test of the valve, it is necessary to collect data such as images, temperature, pressure and leakage, and monitor the test process by connecting cameras and thermocouples to the intelligent control system.

Figure 1 Appearance of fire resistance test equipment of valves

On the control panel of the testing equipment, the temperature of the water inlet end, water outlet end, first and second test points of the valve, central test point and the cooling time are indicated. The sample dropped from 800℃ to 80℃. You can also set the heating time (the time required to heat the sample), heating timing (setting the heating time), test point selection (setting the test point of the sample), and test point selection (selecting the test point of the sample), exhaust (excluding exhaust gas in the test room pipe), gas flow adjustment (adjusting the size of the blowtorch flame) and airflow adjustment (adjusting the airflow required for the test) through the control panel.

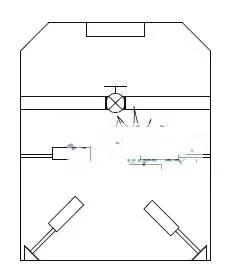

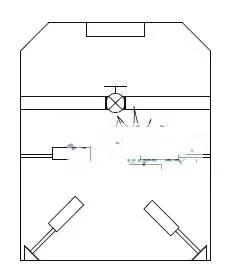

The gas flow of the fire resistance test and detection equipment is controlled by a flow meter (Figure 2). The diameter of the blowtorch is 35mm, and it adopts 3 sets of independent control units; each set contains 4 units, which can be selected and used. There are 3 blowtorches horizontally on one side of the test chamber, 3 blowtorches horizontally on the other side, and 6 blowtorches at an angle of 45 to the horizontal plane on the bottom. All blowtorches are installed in the test chamber through a platform, and the platform is equipped with an arbitrary adjustment device for the combustion angle. The height of the blue flame in the flame ejected by the blowtorch is 55mm; the total height of the flame is 175mm, and the flame size can be adjusted. The blowtorch is connected to the automatic ignition device, and the internal pipes and test valves are connected by flanges, making installation and disassembly easy. The burning time can be set at will and controlled by a timer with an accuracy of 0.1s.

There are 6 groups of temperature test points for the sample, two of which are calorimetric blocks with adjustable positions, and the temperature display adopts switching display mode. The test inlet water temperature and outlet water temperature in the internal pipeline of the test chamber can be monitored in real-time. There is a sample refrigeration device in the test chamber. When the test reaches the set burning time, it will automatically stop burning and enter the sample cooling time. There are two cooling methods, namely natural cooling and water cooling, and the time required for the temperature to drop from 800°C to 80°C is monitored in real-time. The test chamber, exhaust system and internal pipes of the test chamber are all made from stainless steel. The internal boxes of the test chamber are reinforced and waterproofed to ensure stable performance of the equipment in the combustion test and pressurization process. The test bench sample holder, joints and other accessories of the equipment are all made from stainless steel or copper.

Figure 2 Fire resistance test equipment structure

The valve fire resistance test requires that during and after the fire test, when the temperature of the tested valve drops below 100°C, the pressure can be adjusted and maintained and temperature values can be recorded in these three processes. Through the pressure sensor, the test pressure of the tested valve can be displayed on the digital display meter on the pressurizing station. The firing temperature of the detected valve can be monitored in real-time through the thermocouple and displayed on the digital display on the pressurizing station.

When the fire temperature reaches 760°C, manually and gradually reduce the intake air flow; start the residual fire insulation combustion, and manually control the maximum combustion temperature to 980°C. At this time, the fire pressure of the valve will be displayed on the digital display at the pressurizing station. Every 2 minutes during the fire, the system will automatically record the test data of each pressure instrument and temperature instrument. When it is found that water vapor emerges from the vent globe valve in the fire heating process, close the vent globe valve. At this time, the water vapor leaking from the valve under test condenses into water through the condensation tank and flows into the measuring cup. When the entire burning time reaches the set time of 30 minutes, stop the burning test and read the amount of water collected in the measuring cup to obtain the leakage value of the valve under test. After a delay, open the fire furnace door and use a ventilator to forcibly cool the fire chamber until the temperature of the valve drops to 100°C. At this time, continue to collect the leakage water. When the valve temperature drops to 100°C, press the button of the high-pressure water pump motor to close the globe valve and pressure-reducing valve; open the unloading valve, and discharge the high-pressure gas and liquid in the valve pipeline to the return water pipeline. At the same time, record the leakage water volume of the measuring cup and compare it with the value specified in the standard to determine whether the valve that has passed the fire test can meet the fire resistance test requirements specified in the standard.

After the fire is completed, the detection principle is the same as described above when the valve is completely cooled to 20°C. The water pressure test pressure of the tested valve is also displayed on the digital display through the pressure sensor. At the same time, the leakage water volume collected through the measuring cup and the standard value are compared to determine whether the tested valve is qualified. When the fatigue times of the device reach the set value, the system will automatically stop working. When the system pressure exceeds the set pressure, the system will automatically relieve the pressure to ensure the safety of the test process.

4. Conclusion

The testing equipment designed according to the requirements of valve fire resistance test standards realizes intelligent remote control, accurate testing data, real-time monitoring, stable performance, and safe operation, which improves the level and ability of valve quality testing.

Testing Equipment

According to the requirements of fire resistance test standards of the valve, a remotely controlled, safe, reliable and accurate measuring equipment was designed (Figure 1). The heat source for the fire resistance test of the valve uses liquefied natural gas. To ensure the safety of the test, a remote controller was developed. It was believed that the remote control system should send signals to the computer and realize the remote control to adjust the flame and test temperature. During the fire resistance test of the valve, it is necessary to collect data such as images, temperature, pressure and leakage, and monitor the test process by connecting cameras and thermocouples to the intelligent control system.

Figure 1 Appearance of fire resistance test equipment of valves

On the control panel of the testing equipment, the temperature of the water inlet end, water outlet end, first and second test points of the valve, central test point and the cooling time are indicated. The sample dropped from 800℃ to 80℃. You can also set the heating time (the time required to heat the sample), heating timing (setting the heating time), test point selection (setting the test point of the sample), and test point selection (selecting the test point of the sample), exhaust (excluding exhaust gas in the test room pipe), gas flow adjustment (adjusting the size of the blowtorch flame) and airflow adjustment (adjusting the airflow required for the test) through the control panel.

The gas flow of the fire resistance test and detection equipment is controlled by a flow meter (Figure 2). The diameter of the blowtorch is 35mm, and it adopts 3 sets of independent control units; each set contains 4 units, which can be selected and used. There are 3 blowtorches horizontally on one side of the test chamber, 3 blowtorches horizontally on the other side, and 6 blowtorches at an angle of 45 to the horizontal plane on the bottom. All blowtorches are installed in the test chamber through a platform, and the platform is equipped with an arbitrary adjustment device for the combustion angle. The height of the blue flame in the flame ejected by the blowtorch is 55mm; the total height of the flame is 175mm, and the flame size can be adjusted. The blowtorch is connected to the automatic ignition device, and the internal pipes and test valves are connected by flanges, making installation and disassembly easy. The burning time can be set at will and controlled by a timer with an accuracy of 0.1s.

There are 6 groups of temperature test points for the sample, two of which are calorimetric blocks with adjustable positions, and the temperature display adopts switching display mode. The test inlet water temperature and outlet water temperature in the internal pipeline of the test chamber can be monitored in real-time. There is a sample refrigeration device in the test chamber. When the test reaches the set burning time, it will automatically stop burning and enter the sample cooling time. There are two cooling methods, namely natural cooling and water cooling, and the time required for the temperature to drop from 800°C to 80°C is monitored in real-time. The test chamber, exhaust system and internal pipes of the test chamber are all made from stainless steel. The internal boxes of the test chamber are reinforced and waterproofed to ensure stable performance of the equipment in the combustion test and pressurization process. The test bench sample holder, joints and other accessories of the equipment are all made from stainless steel or copper.

Figure 2 Fire resistance test equipment structure

The valve fire resistance test requires that during and after the fire test, when the temperature of the tested valve drops below 100°C, the pressure can be adjusted and maintained and temperature values can be recorded in these three processes. Through the pressure sensor, the test pressure of the tested valve can be displayed on the digital display meter on the pressurizing station. The firing temperature of the detected valve can be monitored in real-time through the thermocouple and displayed on the digital display on the pressurizing station.

When the fire temperature reaches 760°C, manually and gradually reduce the intake air flow; start the residual fire insulation combustion, and manually control the maximum combustion temperature to 980°C. At this time, the fire pressure of the valve will be displayed on the digital display at the pressurizing station. Every 2 minutes during the fire, the system will automatically record the test data of each pressure instrument and temperature instrument. When it is found that water vapor emerges from the vent globe valve in the fire heating process, close the vent globe valve. At this time, the water vapor leaking from the valve under test condenses into water through the condensation tank and flows into the measuring cup. When the entire burning time reaches the set time of 30 minutes, stop the burning test and read the amount of water collected in the measuring cup to obtain the leakage value of the valve under test. After a delay, open the fire furnace door and use a ventilator to forcibly cool the fire chamber until the temperature of the valve drops to 100°C. At this time, continue to collect the leakage water. When the valve temperature drops to 100°C, press the button of the high-pressure water pump motor to close the globe valve and pressure-reducing valve; open the unloading valve, and discharge the high-pressure gas and liquid in the valve pipeline to the return water pipeline. At the same time, record the leakage water volume of the measuring cup and compare it with the value specified in the standard to determine whether the valve that has passed the fire test can meet the fire resistance test requirements specified in the standard.

After the fire is completed, the detection principle is the same as described above when the valve is completely cooled to 20°C. The water pressure test pressure of the tested valve is also displayed on the digital display through the pressure sensor. At the same time, the leakage water volume collected through the measuring cup and the standard value are compared to determine whether the tested valve is qualified. When the fatigue times of the device reach the set value, the system will automatically stop working. When the system pressure exceeds the set pressure, the system will automatically relieve the pressure to ensure the safety of the test process.

4. Conclusion

The testing equipment designed according to the requirements of valve fire resistance test standards realizes intelligent remote control, accurate testing data, real-time monitoring, stable performance, and safe operation, which improves the level and ability of valve quality testing.

Previous: Inspecting Internal Leakages of Buried Ball Valves

Next: Metal Seated Ball Valves in Offshore Platforms (Part One)

Next: Metal Seated Ball Valves in Offshore Platforms (Part One)