Baltic delivered big check valves to BP/ Basra Oil Company in Iraq

On this page

Dual- Plate Check Valve, Wafer, Through Drilled Lug, RETAINERLESS style

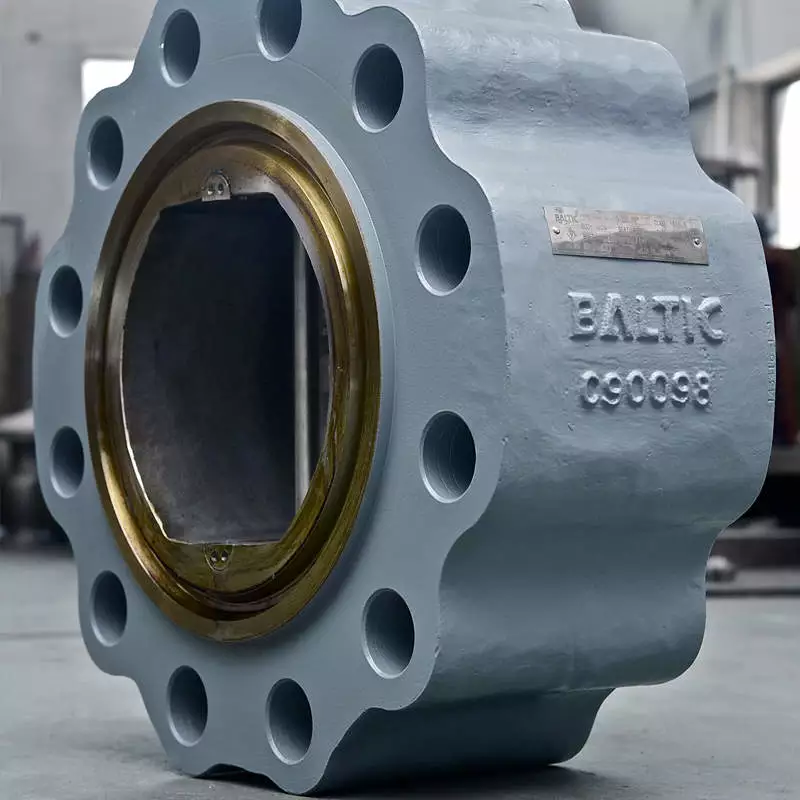

We finished & delivered some big size check valves to BP/ Basra Oil Company in Iraq.

Product description:

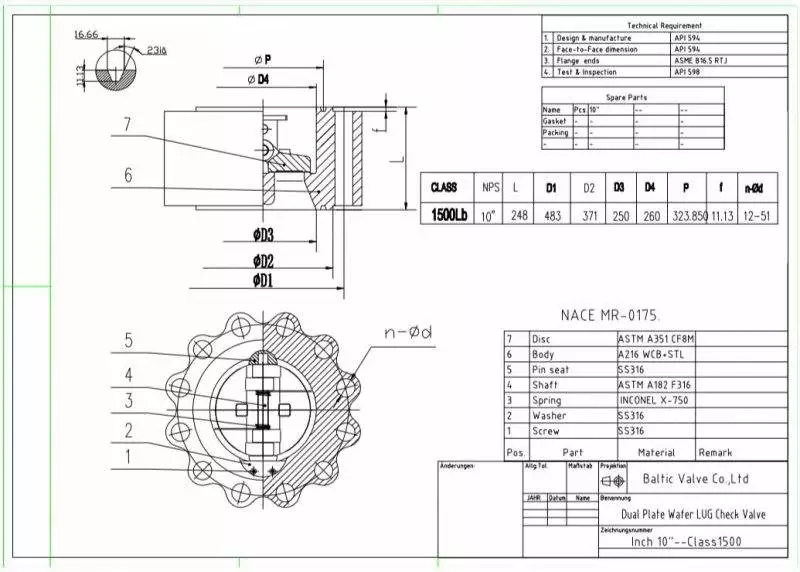

Dual- Plate Check Valve

Design: API 594

Wafer, Through Drilled Lug, Horizontal or Vertical Installation, with Flow Direction

Retainerless Type

Materials:

Body: ASTM A216 WCB

Trim: 16#

Disc: ASTM A351 CF8M + Stellite

Shaft: ASTM A182 F316

Body Seat: Stellite

Spring: Inconel X750

NACE MR0175

Connection: RTJ acc. to ASME B16.5

Face to Face: API 594 = 248mm

Size: 10 Inch

Class: 1500 LB

Qty: 4 PCS

To be strictly adhered to:

Piping Class: A15E2B

Data Sheet: C15A02

Commodity Code: PVCC2SK1RJ67ZC3

Kindly, please find the following copy of our GA drawing, valve picture, data sheet:

GA Drawing

Valve Pictures

Data Sheet

RUMAILA PROJECT

SPECIFICATION FOR BROWNFIELD PIPING CLASS – A15E2B

| VALVE DATA SHEET | |

| VALVE INFORMATION | |

| VALVE TAG NUMBER | C15A02 |

| VALVE TYPE | CHECK, DUAL PLATE (RETAINERLESS) |

| BODY PATTERN | THROUGH DRILLED LUG WAFER TYPE (Note 3) |

| END CONNECTIONS | TO SUIT ASME B16.5 RING TYPE JOINT (Note 4) |

| NOMINAL SIZE RANGE | 2" through 24" |

| VALVE RATING | ASME 1500 PER ASME B16.5 |

| DESIGN SPECIFICATION / QUALITY LEVEL | API 594 |

| REFERENCE STANDARD | ASME B16.34 |

| DESIGN PRESSURE | FULLY RATED PER ASME B16.34 (Note 1) |

| DESIGN TEMPERATURE | -2 / 100 °C |

| DESIGN DIFFERENTIAL PRESSURE | FULL DIFFERENTIAL PRESSURE |

| SERVICE MEDIUM | WATER INJECTION (SOURCE WATER) |

| SOUR SERVICE | YES AS PER NACE MR0175/ISO 15156 |

| FACE TO FACE DIMENSIONS | API 594 |

| CORROSION ALLOWANCE | 3mm (Note 2) |

| MATERIALS OF CONSTRUCTION | |

| BODY/BONNET MATERIAL | CS ASTM A216-WCB |

| OBTURATOR MATERIAL | F316 HARD FACED (API 12 TRIM) |

| STEM MATERIAL | 316 SS |

| SEAT MATERIAL | F316 HARD FACED (API 12 TRIM) |

| SEAT INSERT MATERIAL | N/A |

| BONNET GASKET | N/A |

| SPRING MATERIAL | INCONEL X750 |

| BOLTING MATERIAL | N/A |

| SPECIFIC REQUIREMENTS | |

| OPERATION | N/A |

| NUMBER OF TURNS (OPEN TO CLOSED) | N/A |

| FIRE TEST CERTIFICATION | N/A |

| BODY CAVITY RELIEF | N/A |

| VENT / DRAIN | NOT REQUIRED. |

| HYDRO / PNEUMATIC TEST | API 594 |

| GAS TEST | API 594 |

| SEAT LEAK RATE | API 594 |

| SEAT INJECTION | N/A |

| STEM INJECTION | N/A |

| FUGITIVE EMISSION PACKING / SEALS | REQUIRED |

| GENERAL REQUIREMENTS | |

| DESIGN LIFE | 10 YEARS |

| EXTERNAL PAINTING | MIN 3 COATS, OVERALL DFT NOT LESS THAN 150µM, RAL 000 70 00 |

| MATERIAL CERTIFICATION | 3.1 CERTS FOR PRESSURISED PARTS, 2.2 CERTS FOR OTHER PARTS |

| Notes | |

| 1. Bidder to confirm that valve is fully rated for range of coincidental design temperatures and pressures shown in this specification. | |

| 2. Bidder to confirm that valve has a 3mm corrosion allowance. | |

| 3. Valves shall be able to operate in the horizontal or vertical position with upward flow. | |

| 4. Side wall of gasket groove surface finish not to exceed 1.6 microns roughness per ASME B46.1 | |

| 5. Valves to be supplied with a SS nameplate showing manufacturers name, serial number, size, rating, certification data and tag number. | |

| APPLICABLE PIPING CLASSES - A15E2B | |

0000RP-C-G0-G000-PE-SPC-0005 Rev B03 January 2016 Page 54 of 71

This document is the property of Rumaila Field Develops Projects. It must not be stored, reproduced or disclosed to others without written authorisation from the Company

Previous: Baltic produced big size & high class gate valves to a UK customer

Next: Baltic Delivered Some Big Size Ball Valves to BP & Basra Oil Company in Iraq

Next: Baltic Delivered Some Big Size Ball Valves to BP & Basra Oil Company in Iraq