A Kind of Repair Technology for Check Valves (Part One)

Abstract

During the use of traditional horizontal lift check valves, problems such as damage to the sealing surface and breakage of the spool guide rod will occur due to the influence of liquid corrosion and impurities, which leads to a lot of disassembly and assembly, fast failure, and short service life of the check valve. Change the traditional horizontal lift check valve's structure and sealing method; add a valve sleeve assembly in the cavity of the check valve body, including valve sleeves, valve cores and valve sleeve covers, and change the end face seal to "O" type seals and cone seals. The improved check valve can not only ensure single flow, but also facilitate the disassembly and cleaning of valve components, which can effectively reduce labor intensity and production costs.

A check valve refers to a valve whose opening and closing part is a circular valve plate and is operated by its own weight and medium pressure to block the back flow of the medium. There are many types of check valves. According to the internal structure of check valves, they are mainly divided into lift check valves and swing check valves. Among them, the lift check valve is divided into two types: horizontal lift check valves and vertical lift check valves. In the gathering and transportation system of the oilfield, the traditional horizontal lift check valve is commonly used. This kind of check valve is mainly installed in the outlet of the oil pump and the metering room of the oil well. In the use process, the sealing surface is damaged and the valve core guide rod is broken due to the influence of liquid corrosion and impurities, which causes a lot of disassembly and assembly, fast failure, and short service life of the check valve. Find out a repair technology of check valves to facilitate the maintenance and cleaning of the check valve, improve the performance of the check valve, and extend the service life of the check valve.

During the use of traditional horizontal lift check valves, problems such as damage to the sealing surface and breakage of the spool guide rod will occur due to the influence of liquid corrosion and impurities, which leads to a lot of disassembly and assembly, fast failure, and short service life of the check valve. Change the traditional horizontal lift check valve's structure and sealing method; add a valve sleeve assembly in the cavity of the check valve body, including valve sleeves, valve cores and valve sleeve covers, and change the end face seal to "O" type seals and cone seals. The improved check valve can not only ensure single flow, but also facilitate the disassembly and cleaning of valve components, which can effectively reduce labor intensity and production costs.

A check valve refers to a valve whose opening and closing part is a circular valve plate and is operated by its own weight and medium pressure to block the back flow of the medium. There are many types of check valves. According to the internal structure of check valves, they are mainly divided into lift check valves and swing check valves. Among them, the lift check valve is divided into two types: horizontal lift check valves and vertical lift check valves. In the gathering and transportation system of the oilfield, the traditional horizontal lift check valve is commonly used. This kind of check valve is mainly installed in the outlet of the oil pump and the metering room of the oil well. In the use process, the sealing surface is damaged and the valve core guide rod is broken due to the influence of liquid corrosion and impurities, which causes a lot of disassembly and assembly, fast failure, and short service life of the check valve. Find out a repair technology of check valves to facilitate the maintenance and cleaning of the check valve, improve the performance of the check valve, and extend the service life of the check valve.

1. Traditional horizontal lift check valves

1.1 The structure and working principle of the traditional horizontal lift check valve

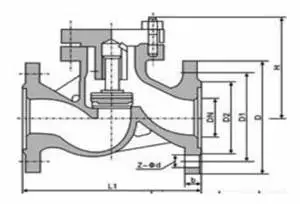

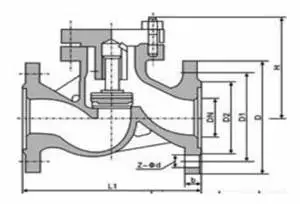

The traditional horizontal lift check valve is mainly composed of the valve body, bonnet, valve core, guide cylinder and guide rod (Figure 1). The guide cylinder is welded to the center of the valve bonnet, and the guide rod is welded to the center of the valve core. The guide rod is sleeved in the guide cylinder to drive the valve core to move vertically up and down under the movement of the fluid medium. When the inlet pressure of the check valve is greater than the outlet pressure, the fluid medium lifts the valve core to form a channel for liquid; when the outlet pressure of the check valve is greater than the inlet pressure, the fluid medium at the outlet side makes the valve core move downward under the action of the pressure difference. At this time, the sealing surface of the lower end of the valve core is in contact with that of the valve body to quickly seal the fluid channel, thereby cutting off the fluid flow and achieving the purpose of preventing the medium from flowing back.

Figure 1 Traditional horizontal check valves

1.2 Problems existing in the traditional horizontal lift check valve

(1) Easily damaged sealing surfaces: The sealing of the traditional horizontal lift check valve is end face sealing. In the oil and gas gathering and transportation system, the flowing medium is mostly a mixture of oil, gas, and water. When the inlet pressure of the check valve is greater than its outlet pressure, the oil, gas, and water mixture will lift the valve core to form a liquid outlet channel. At this time, the oil flow is discontinuous due to the gas and liquid in the medium, resulting in a small pressure difference. At this moment, although the valve core can move up and down under the restriction of the guide rod and guide cylinder, the passage of the check valve which fluid passes through is relatively narrow and the pressure drop is great, causing uneven force on the valve core's surface. The valve core's surface constantly knocks on the valve body's sealing surface, damaging the sealing surface, causing the check valve to fail and affecting the service life of the check valve.

(2) Easy broken spool guide rods: When the oil flow in the pipeline is discontinuous, the valve core surface swings left and right in the valve body cavity under the condition of the uneven force, causing stress concentration at the welding seam of the guide rod and valve core; the guide rod will fall over time, causing the check valve to fail (Figure 2).

Figure 2 The spool and the guide rod being disconnected

The traditional horizontal lift check valve is mainly composed of the valve body, bonnet, valve core, guide cylinder and guide rod (Figure 1). The guide cylinder is welded to the center of the valve bonnet, and the guide rod is welded to the center of the valve core. The guide rod is sleeved in the guide cylinder to drive the valve core to move vertically up and down under the movement of the fluid medium. When the inlet pressure of the check valve is greater than the outlet pressure, the fluid medium lifts the valve core to form a channel for liquid; when the outlet pressure of the check valve is greater than the inlet pressure, the fluid medium at the outlet side makes the valve core move downward under the action of the pressure difference. At this time, the sealing surface of the lower end of the valve core is in contact with that of the valve body to quickly seal the fluid channel, thereby cutting off the fluid flow and achieving the purpose of preventing the medium from flowing back.

Figure 1 Traditional horizontal check valves

1.2 Problems existing in the traditional horizontal lift check valve

(1) Easily damaged sealing surfaces: The sealing of the traditional horizontal lift check valve is end face sealing. In the oil and gas gathering and transportation system, the flowing medium is mostly a mixture of oil, gas, and water. When the inlet pressure of the check valve is greater than its outlet pressure, the oil, gas, and water mixture will lift the valve core to form a liquid outlet channel. At this time, the oil flow is discontinuous due to the gas and liquid in the medium, resulting in a small pressure difference. At this moment, although the valve core can move up and down under the restriction of the guide rod and guide cylinder, the passage of the check valve which fluid passes through is relatively narrow and the pressure drop is great, causing uneven force on the valve core's surface. The valve core's surface constantly knocks on the valve body's sealing surface, damaging the sealing surface, causing the check valve to fail and affecting the service life of the check valve.

(2) Easy broken spool guide rods: When the oil flow in the pipeline is discontinuous, the valve core surface swings left and right in the valve body cavity under the condition of the uneven force, causing stress concentration at the welding seam of the guide rod and valve core; the guide rod will fall over time, causing the check valve to fail (Figure 2).

Figure 2 The spool and the guide rod being disconnected

(3) Difficult maintenance and repair of check valves: In the oil and gas gathering and transportation, the inner cavity of the check valve and its accessories need to be maintained and cleaned frequently due to the corrosion and scaling of the conveying medium.

When the inner sealing surface of the check valve is corroded, the check valve can only be replaced as a whole, because the inner sealing surface of the valve is integrated with the valve body. The check valve needs to be replaced. (Figure 3)

Figure 3 Corrosion of the inner sealing surface of the valve

1.3 The harm caused by the failure of the check valve

When the oil transportation equipment stops running for some reasons, if the check valve fails, the oil flow in the oil pipeline quickly flows back, from the oil transportation equipment-the inlet of the mixed transportation pump to the buffer tank or the air distribution bag. If the workers do not notice in time, it will cause leakages of crude oil.

2. The repair technology of the check valve

2.1 Technical Principles

Change the traditional horizontal lift check valve's structure and sealing method; add valve sleeve assembly in the cavity of the check valve body, and the valve sleeve assembly includes valve sleeves, valve cores and valve sleeve cover plates and other components (Figure 4). The valve sleeve and sealing surface of the valve body are compressed and sealed with an "O" type sealing ring, and the valve core and valve sleeve are sealed with an "O" type sealing ring on a certain angle conical surface. The improved check valve can not only ensure single flow, but also facilitate the disassembly and cleaning of valve components.

Figure 4 The schematic diagram of valve covers, valve cores and valve sleeves

Previous: Top Entry Metal Seated Butterfly Valves

Next: A Kind of Repair Technology for Check Valves (Part Two)

Next: A Kind of Repair Technology for Check Valves (Part Two)