Measures to Prevent Failure of Strength of Lead Brass Valve Shells (Part two)

4. Specifications for the annealing process

When the hot forging shell material of the lead brass valve undergoes plastic deformation, there will be residual stress, and there will also be stress inside it due to external load in the subsequent cutting process. In the environment of ammonia, SO₂ and humid corrosion, the combination of residual stress and external stress will cause the shell to fail due to stress corrosion cracking. At present, the annealing process for the shell commonly used in the industry is stress-relieving annealing for forging blanks and annealing after cutting. The stress relief annealing temperature of the forging blank should be 350 to 400°C. The stress relief annealing temperature after cutting should be 270 to 300°C. Comparing the two annealing processes, the metallographic structure of the α-phase in the stress-relieving annealing process of the hot-forged blank has the shape of a thick band (Figure 1a), while the α-phase in the stress-relief annealing process after cutting is equiaxed or thin and short rod-shaped (Figure 1b). The grain is finer than the former, which ensures the improvement of the strength of the shell.

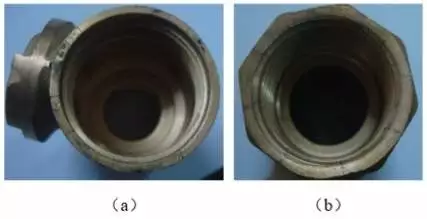

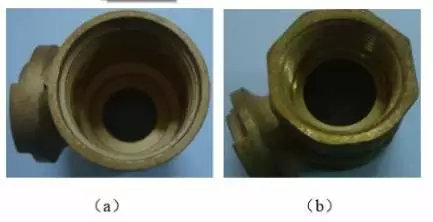

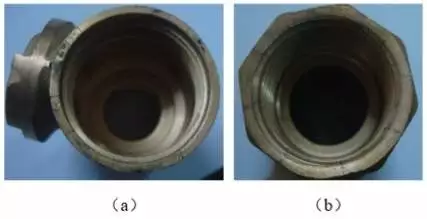

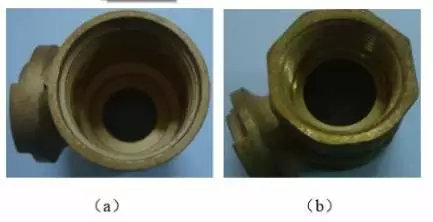

The comparative test of the above-mentioned different annealing processes was carried out. After 24 hours of ammonia fumigation tests, the internal residual stress of the shell is relatively great under the process conditions of annealing and cutting of forging to the finished product since there are many cracks at the thread of the valve body (Figure 2), which greatly affects the strength and sealing of the product. It can be seen that the stress relief annealing of the forging blank only eliminates the residual stress when the hot forging undergoes plastic deformation. The annealing temperature of the forging blank is relatively high, which leads to the increase in the aggregation of lead particles, reduces the number of lead particles per unit area and the cutting of the material, and increases the stress in the subsequent cutting process. There are no visible and obvious cracks on the surface of the product after cutting and annealing (Figure 3), and the internal residual stress in the two steps of hot forging and cutting of blank is eliminated. Therefore, annealing after cutting is the first choice in the annealing process. If conditions permit, the above two annealing methods can be combined.

(a) Multiple cracks at the end of the thread on the mouth surface (b) Multiple cracks at the end of the pipe thread

Figure 2 The surface crack of the forging after the stress relief annealing ammonia fumigation test

(a) No crack at the end of the threaded surface of the mouth (b) No crack at the end of the pipe thread

Figure 3 No visible cracks on the surface of the shell after annealing after cutting and helium fumigation test

5. Matters needing attention in the installation process

Common lead brass valves are connected to galvanized pipes by threads during installation. When installing, first ensure the matching degree of pipe threads, standardize the management of tightening torque, and follow the principle of the same side wrench to avoid cracking caused by superposition of installation stress. In addition, it is necessary to reasonably control the screwing length of the pipe fittings to prevent the valve’s sealing surface from being deformed or damaged by the pipe fittings, causing the product to crack and fail.

6. Conclusion

To ensure that lead brass valves have good strength, appropriate grades should be selected in combination with relevant standards, and the control of main elements and impurities should be strengthened. In the manufacturing process, the process of each link should be strictly regulated. The forging temperature should be slightly lower than the transition temperature of α plus β or β of the selected grade, and the heating temperature of the copper rod should be appropriately increased according to the actual copper content. When heating, it is necessary to pay attention to quickly passing through the temperature range of a large number of α phase transitions and try to avoid this temperature range for heat preservation. Choose a suitable stress relief annealing process to avoid cracking caused by the combination of valve corrosion stress and external stress. In the process of actual installation and use, attention should be paid to the standard installation to prevent brutal construction. Through the above measures, the failure probability of the strength of the valve shell is greatly reduced, the service life of the lead brass valve is extended, and a guarantee is provided for a healthy water supply, safe gas supply, and efficient heating supply in cities and towns.

When the hot forging shell material of the lead brass valve undergoes plastic deformation, there will be residual stress, and there will also be stress inside it due to external load in the subsequent cutting process. In the environment of ammonia, SO₂ and humid corrosion, the combination of residual stress and external stress will cause the shell to fail due to stress corrosion cracking. At present, the annealing process for the shell commonly used in the industry is stress-relieving annealing for forging blanks and annealing after cutting. The stress relief annealing temperature of the forging blank should be 350 to 400°C. The stress relief annealing temperature after cutting should be 270 to 300°C. Comparing the two annealing processes, the metallographic structure of the α-phase in the stress-relieving annealing process of the hot-forged blank has the shape of a thick band (Figure 1a), while the α-phase in the stress-relief annealing process after cutting is equiaxed or thin and short rod-shaped (Figure 1b). The grain is finer than the former, which ensures the improvement of the strength of the shell.

The comparative test of the above-mentioned different annealing processes was carried out. After 24 hours of ammonia fumigation tests, the internal residual stress of the shell is relatively great under the process conditions of annealing and cutting of forging to the finished product since there are many cracks at the thread of the valve body (Figure 2), which greatly affects the strength and sealing of the product. It can be seen that the stress relief annealing of the forging blank only eliminates the residual stress when the hot forging undergoes plastic deformation. The annealing temperature of the forging blank is relatively high, which leads to the increase in the aggregation of lead particles, reduces the number of lead particles per unit area and the cutting of the material, and increases the stress in the subsequent cutting process. There are no visible and obvious cracks on the surface of the product after cutting and annealing (Figure 3), and the internal residual stress in the two steps of hot forging and cutting of blank is eliminated. Therefore, annealing after cutting is the first choice in the annealing process. If conditions permit, the above two annealing methods can be combined.

(a) Multiple cracks at the end of the thread on the mouth surface (b) Multiple cracks at the end of the pipe thread

Figure 2 The surface crack of the forging after the stress relief annealing ammonia fumigation test

(a) No crack at the end of the threaded surface of the mouth (b) No crack at the end of the pipe thread

Figure 3 No visible cracks on the surface of the shell after annealing after cutting and helium fumigation test

5. Matters needing attention in the installation process

Common lead brass valves are connected to galvanized pipes by threads during installation. When installing, first ensure the matching degree of pipe threads, standardize the management of tightening torque, and follow the principle of the same side wrench to avoid cracking caused by superposition of installation stress. In addition, it is necessary to reasonably control the screwing length of the pipe fittings to prevent the valve’s sealing surface from being deformed or damaged by the pipe fittings, causing the product to crack and fail.

6. Conclusion

To ensure that lead brass valves have good strength, appropriate grades should be selected in combination with relevant standards, and the control of main elements and impurities should be strengthened. In the manufacturing process, the process of each link should be strictly regulated. The forging temperature should be slightly lower than the transition temperature of α plus β or β of the selected grade, and the heating temperature of the copper rod should be appropriately increased according to the actual copper content. When heating, it is necessary to pay attention to quickly passing through the temperature range of a large number of α phase transitions and try to avoid this temperature range for heat preservation. Choose a suitable stress relief annealing process to avoid cracking caused by the combination of valve corrosion stress and external stress. In the process of actual installation and use, attention should be paid to the standard installation to prevent brutal construction. Through the above measures, the failure probability of the strength of the valve shell is greatly reduced, the service life of the lead brass valve is extended, and a guarantee is provided for a healthy water supply, safe gas supply, and efficient heating supply in cities and towns.