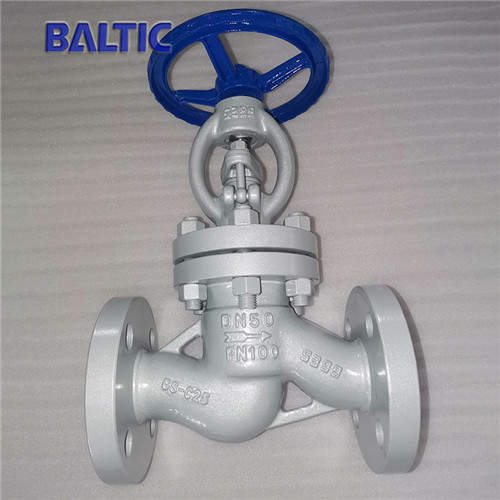

Globe Valve

A globe valve is a kind of valve whose closing part (disc) moves along the center line of the valve seat. Because the opening or closing stroke of the valve stem is relatively short, the valve has a very reliable cut-off function, and the change of valve seat opening is proportional to the stroke of the disc, the valve is very suitable to regulate the flow. Therefore, this type of valve is the ideal choice for cutting off or regulating the medium and throttling.

A bellows seal globe valve boasts high performance elastic metal bellows, which are manufactured by introducing foreign advanced technology and adopting foreign metal bellows sealing technology. Its fatigue life is particularly long. The design of bellows seal completely eliminates the shortcomings of quick aging and easy leakage of ordinary valve stem packing seal. It does not only improve the energy efficiency, increases the safety of production equipment, reduces the maintenance cost, but also provides a clean and safe working environment.

Structure:

1. Double seal design (bellows + packing). If the bellows fails, the stem packing will avoid leakage.

2. Reasonable structure, reliable sealing, excellent performance and beautiful appearance.

3. No fluid loss. It can reduce energy losses and improve the safety of plant equipment.

4. The sealing surface is overlaid with Co based cemented carbide, which has good wear resistance, anti-corrosion, friction resistance, long service life, reducing maintenance times and operating costs.

5. Strong and durable bellows seal design ensures zero leakage of the valve stem and provides free maintenance.

6. The valve stem has good anti-corrosion and friction resistance by quenching and tempering, and surface nitriding treatment.

7. The indication of the valve stem lifting position is more intuitive.

Structure:

1. Double seal design (bellows + packing). If the bellows fails, the stem packing will avoid leakage.

2. Reasonable structure, reliable sealing, excellent performance and beautiful appearance.

3. No fluid loss. It can reduce energy losses and improve the safety of plant equipment.

4. The sealing surface is overlaid with Co based cemented carbide, which has good wear resistance, anti-corrosion, friction resistance, long service life, reducing maintenance times and operating costs.

5. Strong and durable bellows seal design ensures zero leakage of the valve stem and provides free maintenance.

6. The valve stem has good anti-corrosion and friction resistance by quenching and tempering, and surface nitriding treatment.

7. The indication of the valve stem lifting position is more intuitive.

1. It is simple in structure and convenient in manufacture and maintenance.

2. The working stroke is small and the opening and closing time is short.

3. Good sealing performance, small friction between sealing surfaces and long service life.

2. The working stroke is small and the opening and closing time is short.

3. Good sealing performance, small friction between sealing surfaces and long service life.

1. A globe valve uses the stem pressure to make the sealing surface of the disc and the sealing surface of the valve seat fit tightly to cut off the medium. It's a forced seal valve.

2. Flow direction of media in a globe valve includes "low in and high out" and "high in and low out". The medium is allowed to flow in only one direction. The valve shall be installed in right direction.

3. A globe valve has structure of straight-through type, direct flow type and right angle type.

4. When a globe valve is open, and the opening height of the disc is up to 25%-30% of nominal diameter of the globe valve, the flow reaches the maximum, which shows that the valve is in a fully open position.

2. Flow direction of media in a globe valve includes "low in and high out" and "high in and low out". The medium is allowed to flow in only one direction. The valve shall be installed in right direction.

3. A globe valve has structure of straight-through type, direct flow type and right angle type.

4. When a globe valve is open, and the opening height of the disc is up to 25%-30% of nominal diameter of the globe valve, the flow reaches the maximum, which shows that the valve is in a fully open position.