Causes and Measures of Defects of Heavy Hammer Check Valves

Descriptions and causes of defects

After a long-term operation, the main defects and causes of the heavy hammer check valve are shown in Table 1.

Table 1 Defects and causes of heavy hammer check valves

After a long-term operation, the main defects and causes of the heavy hammer check valve are shown in Table 1.

Table 1 Defects and causes of heavy hammer check valves

| Items | Descriptions of defects | Causes of defects |

| 1 | The outlet check valve does not automatically close after the fan is out of service. | The connecting rod pin is loose. |

| 2 | After the fan is out of service, the feedback of a sudden close is sent. The valve is actually at the open position. | Feedback switches are not compacted. |

| 3 | Valve positions display failures. | The limit position of the valve switch is improper. |

| 4 | The direction indicated by the valve's heavy hammer is inaccurate. | The connecting rod pin is loose. |

| 5 | Screws at the valve's indicating device and the connecting rod of the air duct are missing. | The pin between the heavy hammer and the connecting rod is loose. |

| 6 | Screws of connecting rods of check valve heavy hammers fall off. | The connecting rod pin is loose. |

| 7 | The valve does not go back to the seat. | The connecting rod pin is loose. |

| 8 | The leakage in the valve exceeds the standard measured by the instrument monitors. | The sealing ring is damaged. |

1. The analysis of Types and causes of defects

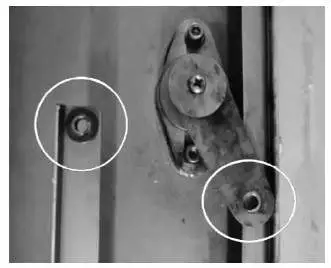

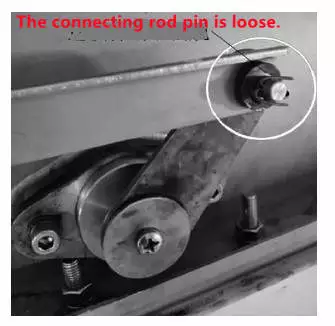

(1) Failure 1: The pin of the connecting rod is loose or lost. There are two main reasons: First, there are some defects in the valve design. The pins between the check valve's connecting rods are fixed by the circlips. When the valve swings back and forth due to opening and closing for a long time, the circlips are easy to loosen, causing the pins to fall off. (Figure 1). Second, the connecting rod's pin bushing is worn. When the fan is started, the valve is in the fully open position. At this time, the heavy hammer and the connecting rod swing continuously. As time increases, the bushing is worn and the pin falls off.

Figure 1 The loose pin of the connecting rod

(2) Failure 2: There is a problem with limit switches. The main reason for this is a design flaw in the check valve's limit switch (Figure 2). With the start and stop of the fan, the valve is continuously opened and closed, and the frequency of the pusher hitting the limit switch increases; the limit switch is damaged as the running time increases. Looseness of the limit switch bracket may also cause the problem of the feedback not being displayed.

Figure 2 The problem with the limit switch

(3) Failure 3: The connecting bolt between the heavy hammer and the valve stem is loose. The analysis believes that the bolts are not fastened well after the valve is repaired. The valve stem is continuously opened and closed with the blades under the action of the heavy hammer, and the connecting bolts between the heavy hammer and the valve stem are the stressed parts, which will cause the bolts to loosen, fall off or even be lost after long-term operation.

2. Measures

(1) The pin of the connecting rod falling off or being lost can be solved by replacing the connection method of the circlip and the pin with the open type, so that the pin is firmer and more reliable, which eliminates the problem of back-and-forth swing of the check valve in the long-term. The movement will cause the circlip to fall off, which will cause the pin to fall off. If the pin falls, the valve cannot be opened and closed normally (Figure 3). Regularly check the wear of the copper sleeve; if the wear is too much, replace the copper sleeve in time to avoid the phenomenon that the system cannot work normally due to the excessive wear of the copper sleeve.

Figure 3 Using a split pin for the connecting rod pin

(2) There are two ways to solve the problem of limit switches: one is to replace the form or the installation method of the limit switch; the other is to change the structure of the pusher to reduce the slope of the contact with the limit switch. Make the pusher contact the limit switch gently instead of pressing the limit switch directly, which can not only increase the stability of the contact with the limit switch, but also reduce the frequent damage, costs and maintenance times of the limit switch.

(3) Double nuts are used for the connecting bolts between the heavy hammer and the valve stem to prevent the heavy hammer from driving the valve stem frequently, causing the nuts to loosen and fall off, which affects the operating state of the system, and achieves the purpose of preventing loosening.

3. Conclusion

The heavy hammer check valve plays a very important role in the ventilation system of the nuclear power plant. By summarizing the defects of the on-site valve such as not getting back to the seat, signal feedback, inaccurate direction of the heavy hammer and valve position display in the working process and combining the operating state of the system and the structure of the valve, it is found that the reason why the valve does not return to the seat and the direction of the heavy hammer is not accurate is at the pin of the connecting rod. The reason for the signal feedback and valve position display is on the limit switch. The solution is explained in detail; the stable operation of the system is ensured and the workload of daily maintenance is reduced.