Ball Valve

A ball valve is widely used in petroleum refining, long-distance pipeline, chemical industry, paper-making, pharmaceutical, water conservancy, electric power, steel and other industries, and plays an important role in economy.

The ball valve in the pipeline is mainly used to cut off, distribute and change the flow direction of the medium. It only needs to rotate 90 degrees with small torque to close tightly. It is opened when the hole of the ball is in line with the flow and closed when it is pivoted 90-degrees.

According to structure, a ball valve can be classified into three classes: floating ball valves, trunnion mounted ball valves, multi way ball valves.

According to connections, the ball valve can fall into flanged ball valves, fully welded ball valves and socket welded ball valves, ring type jointed (RTJ) ball valves.

According to materials used for the body, a ball valve can be divided into casting ball valves, forged ball valves, stainless steel ball valves, etc. According to materials used for the seat, the ball valve can be classified into soft seated ball valves and metal seated ball valves.

According to function, a ball valve falls into single ball valves, DBB ball valves and monoflange ball valves.

If you have any questions about our Ball Valves, pls contact [email protected]!

The ball valve in the pipeline is mainly used to cut off, distribute and change the flow direction of the medium. It only needs to rotate 90 degrees with small torque to close tightly. It is opened when the hole of the ball is in line with the flow and closed when it is pivoted 90-degrees.

According to structure, a ball valve can be classified into three classes: floating ball valves, trunnion mounted ball valves, multi way ball valves.

According to connections, the ball valve can fall into flanged ball valves, fully welded ball valves and socket welded ball valves, ring type jointed (RTJ) ball valves.

According to materials used for the body, a ball valve can be divided into casting ball valves, forged ball valves, stainless steel ball valves, etc. According to materials used for the seat, the ball valve can be classified into soft seated ball valves and metal seated ball valves.

According to function, a ball valve falls into single ball valves, DBB ball valves and monoflange ball valves.

If you have any questions about our Ball Valves, pls contact [email protected]!

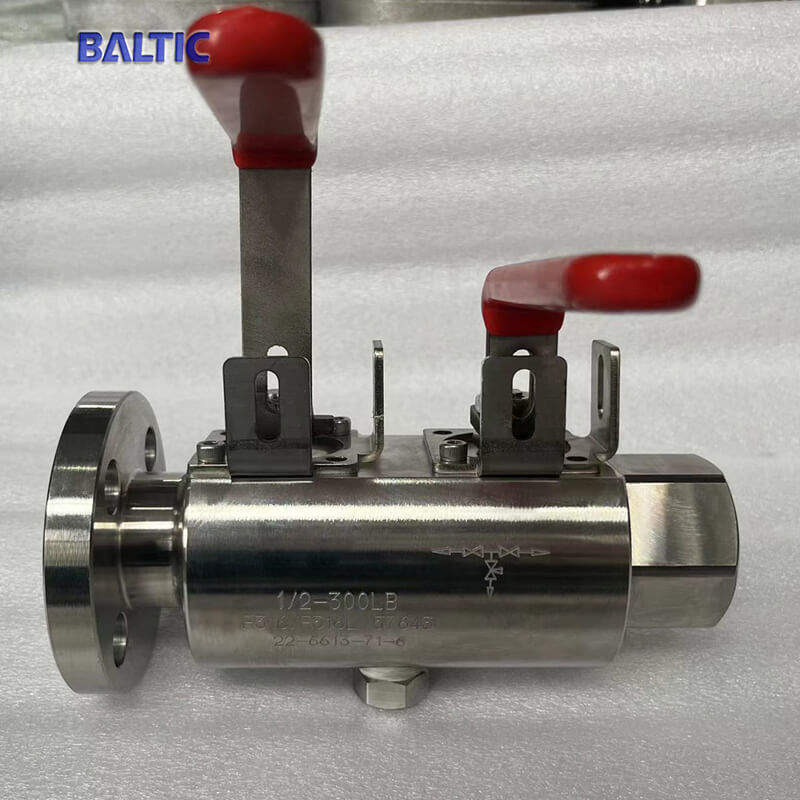

BALTIC Floating Ball Valves are designed,constructed, and tested according to API and ASME/ANSI Standards. Other international standards including BS and DIN are also available on request.

Flanged Floating Ball Valves Specifications

Size Range: 1/2 Inch - 10 Inch

Pressure Class: Class 150 - 600 LB

API Standards: API 6D & API 608

Design: ASME B16.34

FEATURES

Unibody – Reduced Bore

Split body – Full & Reduced Bore

Anti-Blow Out Stem

Anti-Static Device

Firesafe to API 607/6FA

Zero Emissions from Stem

NACE MR-01-75

Flanged Floating Ball Valves Specifications

Size Range: 1/2 Inch - 10 Inch

Pressure Class: Class 150 - 600 LB

API Standards: API 6D & API 608

Design: ASME B16.34

FEATURES

Unibody – Reduced Bore

Split body – Full & Reduced Bore

Anti-Blow Out Stem

Anti-Static Device

Firesafe to API 607/6FA

Zero Emissions from Stem

NACE MR-01-75

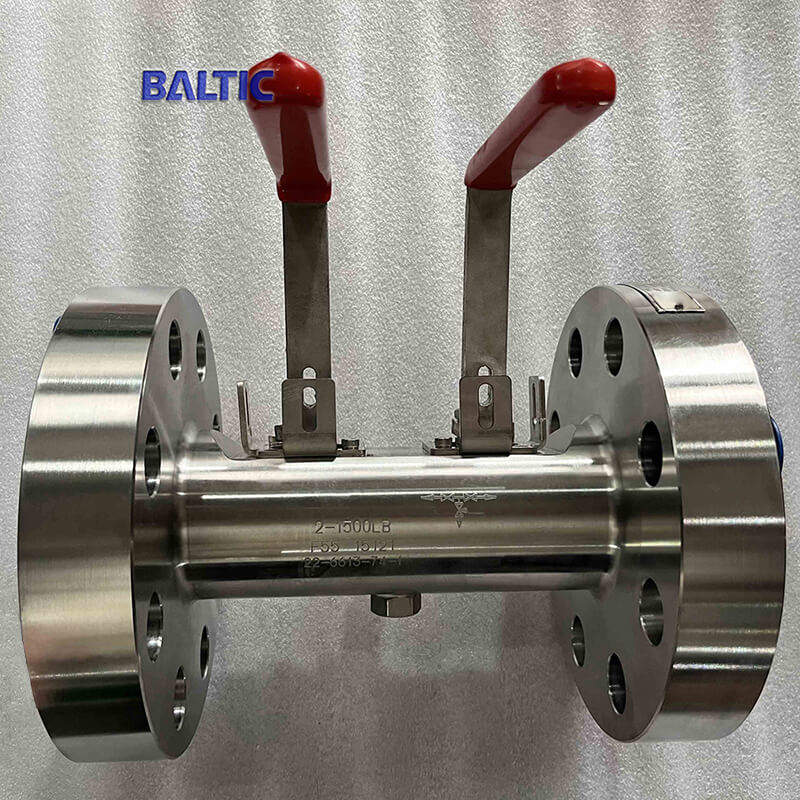

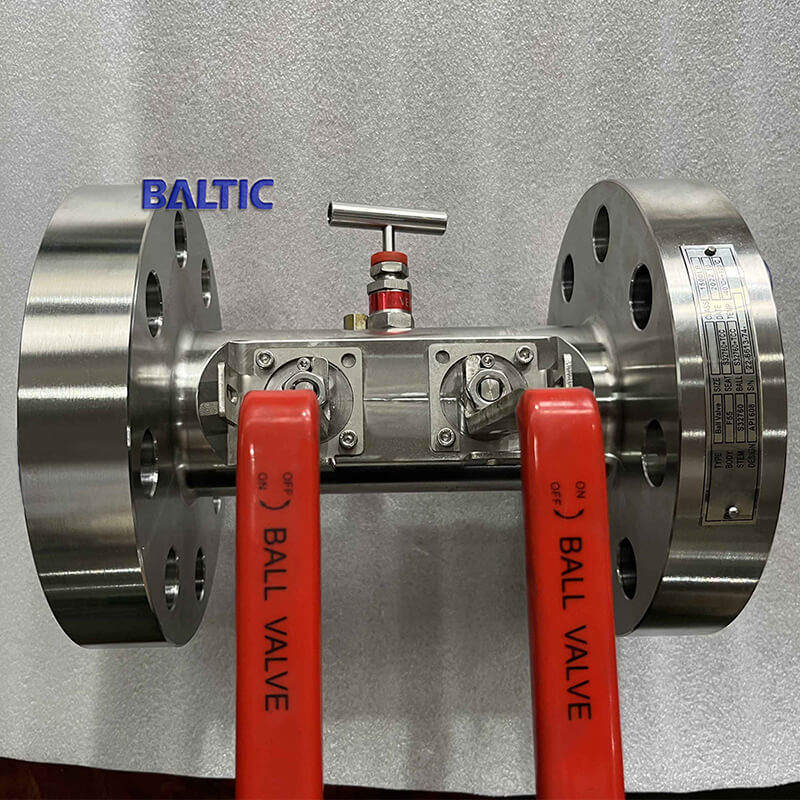

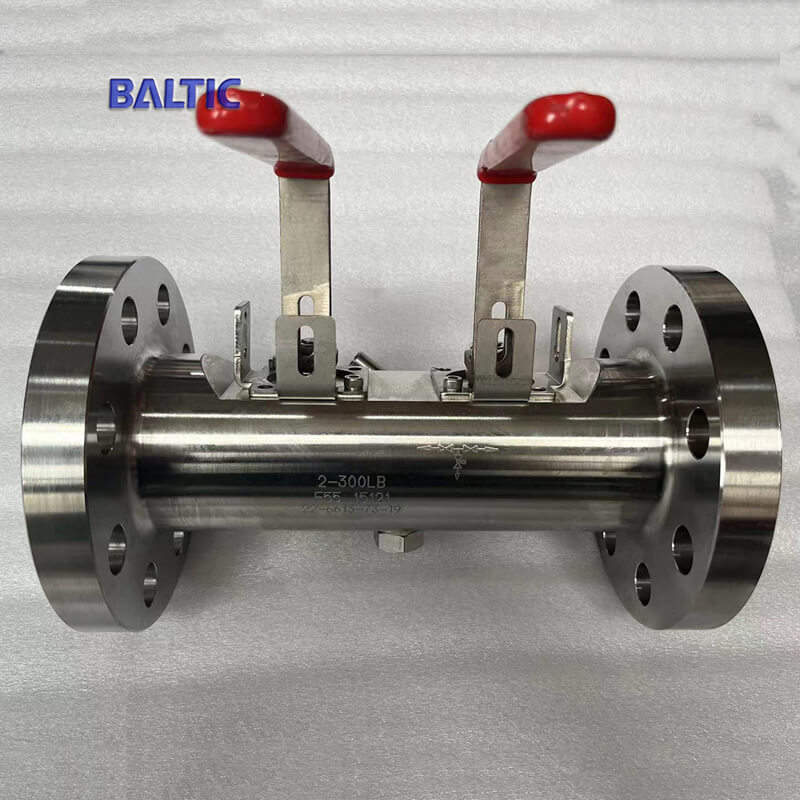

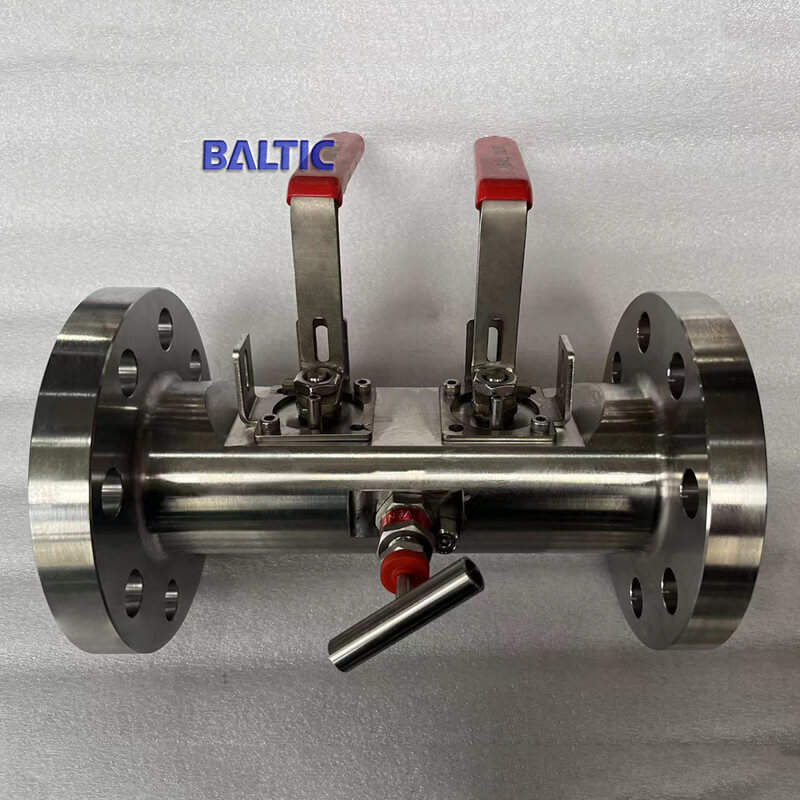

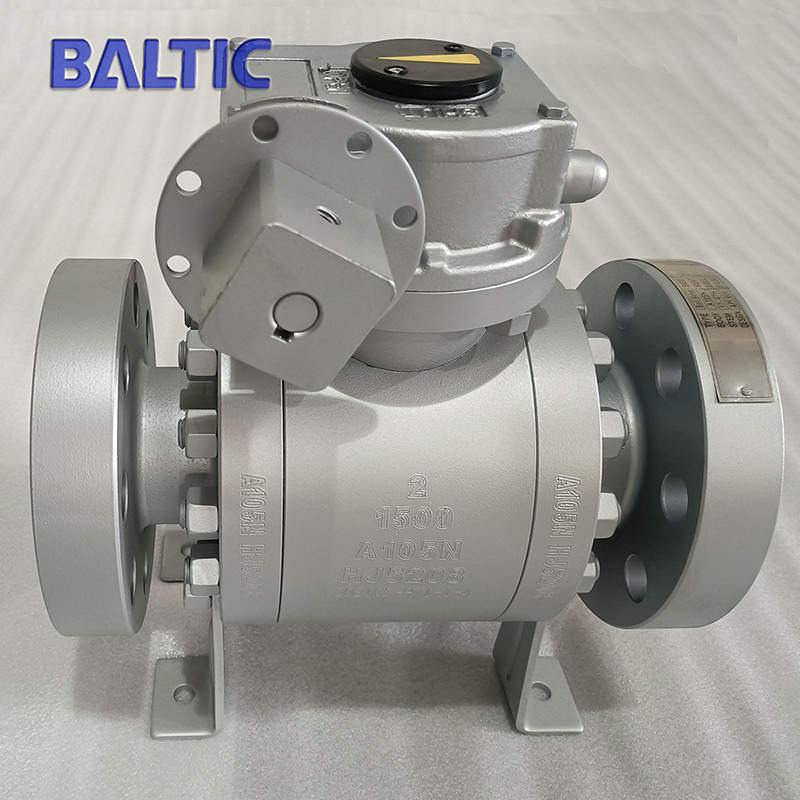

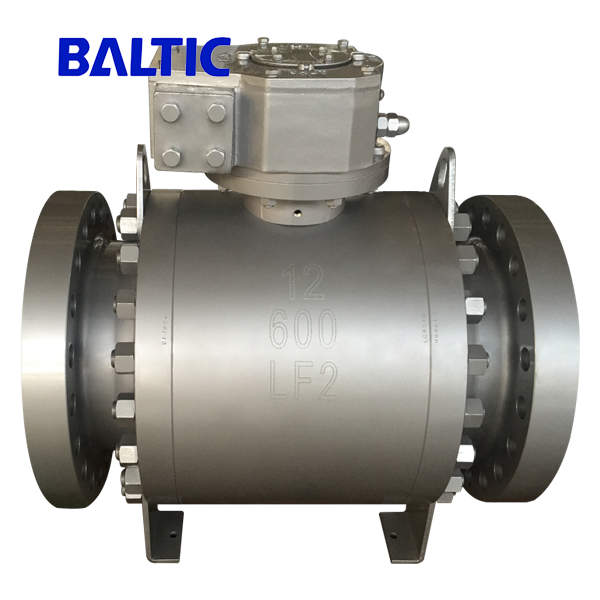

BALTIC Valve produces a full line of API 6D Trunnion Mounted Ball valves in both Three-Piece Forged and Two-Piece Cast Design. We offer a full range of materials—carbon, alloy and stainless steel—from general to severe applications.

Trunnion Mounted Ball Valves Specifications

Size Range: 2 Inch - 48 Inch

Pressure Class: Class 150 - 2500 LB

API Standards: API 6D, API 6A, API 2000 - 5000

Design: ASME B16.34

FEATURES

Three-Piece Body Forged

Two-Piece Body Cast

Full and Reduced Bore

Trunnion Mounted

Double Block and Bleed

Anti-Blowout Stem

Anti-Static Device

Fire Safe to API 607/6FA

Spring Loaded Seats

Sealent Injection

NACE MR-01-75

Trunnion Mounted Ball Valves Specifications

Size Range: 2 Inch - 48 Inch

Pressure Class: Class 150 - 2500 LB

API Standards: API 6D, API 6A, API 2000 - 5000

Design: ASME B16.34

FEATURES

Three-Piece Body Forged

Two-Piece Body Cast

Full and Reduced Bore

Trunnion Mounted

Double Block and Bleed

Anti-Blowout Stem

Anti-Static Device

Fire Safe to API 607/6FA

Spring Loaded Seats

Sealent Injection

NACE MR-01-75