Applications of Rapid Make-up and Release Devices to Oil Plug Valves

On this page

Abstract: The oil plug is heavy and has a smooth outer wall. It is prone to deflection and slow to install. The slow installation speed of the plug significantly restricts and delays the entire well shut-in procedure, increasing the risk of an uncontrolled blowout. The newly developed device has a reasonable structure and is easy to operate. The innovation lies in the plug being equipped with handrails and steering wheels, which can be easily engaged and disengaged at will.

The make-up and release device is a crucial component in downhole operations, particularly during the process of lifting and lowering the pipe column. Oil plug valves are widely used in the development and maintenance of oil and gas fields due to their simple structure, small size, light weight, ease of processing, low cost, and convenient use.

The make-up and release device is a crucial component in downhole operations, particularly during the process of lifting and lowering the pipe column. Oil plug valves are widely used in the development and maintenance of oil and gas fields due to their simple structure, small size, light weight, ease of processing, low cost, and convenient use.

1. Applications of Oil Plug Valves

The oil plug valve is a manually operated control valve used to open and close the pipe circulation system. It is typically used in oil and gas testing, well repair, maintenance, and other related processes to prevent and control blowouts. It can quickly block the oil pipe, preventing fluid from spraying out of the ground and ensuring the safety of production and construction.

2. Structure of Oil Plug Valves

The oil plug valve consists of a body, upper and lower valve seats, a ball, a rotary switch, a sealing ring, a spring, and a clamping cap. It is operated by rotating the inner hexagon on the outer surface to align with the corresponding markings, allowing the valve to open or close.

3. Characteristics of Oil Plug Valves

The oil plug valve is a manually operated blowout prevention valve designed to block fluid in the tubing column. The oil plug valve is installed on the final section of the tubing. In the event of an emergency, such as a well blowout, the oil plug valve can be used to block the inner bore of the tubing column, preventing further blowout incidents. Under normal circumstances, the oil plug valve remains open. In an emergency, such as overflow or a well blowout, the on-site staff should immediately close the oil plug valve to prevent fluid from spraying out of the wellbore through the tubing column and wellhead. If surface pipelines, such as water hoses, blowout preventer pipelines, and well-killing pipelines, are damaged during normal construction, the on-site staff can use the oil plug valve to shut down the well, allowing for safe replacement and repair of the equipment.

4. Precautions for Using Oil Plug Valves at the Construction Site

(1) There should be some space for rotary to allow quick well sealing in abnormal situations.

(2) The oil plug valve should be used in conjunction with the 2SFZ18-14/21 semi-full well sealer. It is intended only for temporary well sealing and should not be used for throttling.

(3) The construction site must be equipped with at least two qualified oil plug valves. The male end of each valve should be coated with thread oil and wrapped with sealing tape.

(4) Two oil plug valves should be present on-site: one placed on the well control tool table next to the wellhead in the open position, and the other connected to the blowout preventer, also in the open position.

Currently, Yanchang Oilfield has fully implemented HSE management and actively learns from CNPC, Sinopec, and other oilfields to strictly control quality. This requires all employees to enhance their quality awareness, utilize their expertise, focus on the details, and eliminate factors that hinder safe production and compromise operational quality. To address the shortcomings of the plug structure, which is prone to deflection and slow to install, a make-up and release device is developed. Field application has shown that the device achieves good results.

(2) The oil plug valve should be used in conjunction with the 2SFZ18-14/21 semi-full well sealer. It is intended only for temporary well sealing and should not be used for throttling.

(3) The construction site must be equipped with at least two qualified oil plug valves. The male end of each valve should be coated with thread oil and wrapped with sealing tape.

(4) Two oil plug valves should be present on-site: one placed on the well control tool table next to the wellhead in the open position, and the other connected to the blowout preventer, also in the open position.

Currently, Yanchang Oilfield has fully implemented HSE management and actively learns from CNPC, Sinopec, and other oilfields to strictly control quality. This requires all employees to enhance their quality awareness, utilize their expertise, focus on the details, and eliminate factors that hinder safe production and compromise operational quality. To address the shortcomings of the plug structure, which is prone to deflection and slow to install, a make-up and release device is developed. Field application has shown that the device achieves good results.

5. Current Situation Analysis and Existing Problems

In recent years, the well control safety situation has remained severe. Well control safety has always been the weak link in oilfield safety management. If any link or procedure is not properly in place, serious accidents may occur, making well control work a critical matter. Currently, factors such as water injection, well shut-ins, formation characteristics, and production enhancement measures like perforation acidification and fracturing have made formation pressure highly unpredictable, leading to frequent sudden blowouts and presenting severe challenges to well control at underground operation sites. The suddenness, speed, and unpredictability of blowouts are the major challenges faced in well control safety. Therefore, controlling the wellhead and shutting down the well as quickly as possible after a blowout is crucial to effective blowout control.

In practice, due to the working environment, operators' gloves often become slippery, and the plug is heavy with a smooth outer wall, making it prone to buckling and slow to install. The slow installation speed of the plug significantly delays the entire well shut-in procedure, increasing the risk of an uncontrolled blowout. Therefore, improving the installation speed of the plug, shortening well shut-in time, and quickly controlling the situation are the primary issues that must be addressed.

In practice, due to the working environment, operators' gloves often become slippery, and the plug is heavy with a smooth outer wall, making it prone to buckling and slow to install. The slow installation speed of the plug significantly delays the entire well shut-in procedure, increasing the risk of an uncontrolled blowout. Therefore, improving the installation speed of the plug, shortening well shut-in time, and quickly controlling the situation are the primary issues that must be addressed.

6. The Main Workload and Work Content Completed

After extensive research, long-term consideration, and numerous field experiments, the plug valve rapid make-up and release device was successfully developed by the end of June 2019 and was put into trial in July. It has been widely used at construction sites.

7. Structure, Working Principle, and Design Process Diagram

7.1 Structure

The device consists of two parts: a three-hole ring and three handles. The wall thickness of the three-hole ring is 10 mm. Three 16 mm internally threaded through holes are evenly distributed along the axis and circumference. The inner diameter of the three-hole ring is slightly larger than the outer diameter of the plug. The handle is a solid rod with an external square at one end and an external thread at the other. The length of the external thread is sufficient to secure the outer wall of the plug, allowing the three-hole ring and the plug to be relatively fixed together.

7.2 Working Principle and Usage

First, screw the handle of the plug valve quick-release device into the threaded hole, then place the three-hole ring around the outside of the plug and position it in the middle-upper part of the plug (ensure the internal hexagonal hole of the plug remains open to avoid interference with the plug's operation). Next, screw in the three handles and tighten them against the plug, ensuring that the handle and plug remain stationary relative to each other even with minimal torque. This completes the installation of the plug valve quick-release device, leaving it in standby mode. When the plug needs to be installed, it can be immediately placed into the female buckle of the pipe column, and the device's handle can be grasped with both hands and rotated to secure the plug. This not only straightens the plug and prevents deflection but also mitigates the issue of slippery gloves, which can make it difficult to secure the plug. This significantly improves the speed and efficiency of the buckling process, thereby enhancing operational safety. Once the thread is fully engaged, tighten it with a pipe clamp. The unthreading process follows a similar method, saving time and effort while being convenient and fast.

7.3 Drawings

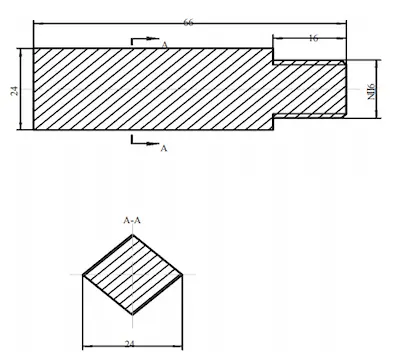

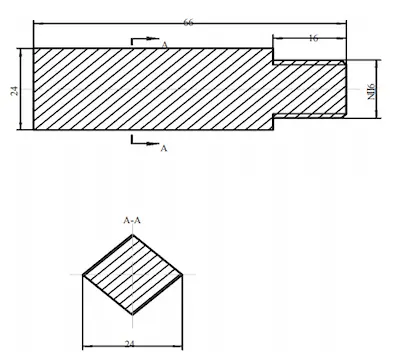

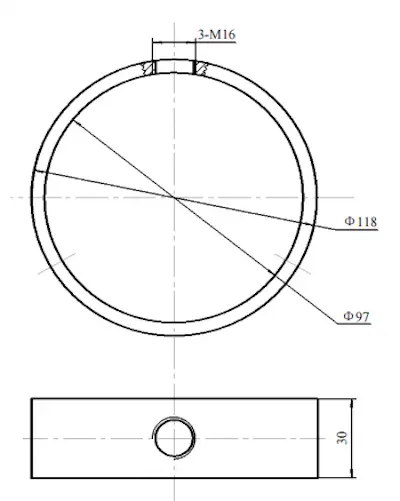

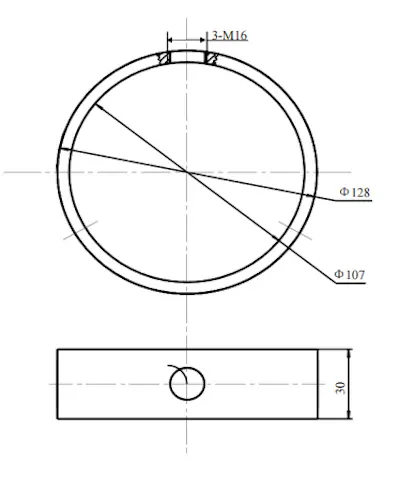

Parts drawings of the plug rapid make-up and release device (Figure 1 to Figure 3)

Figure 1 Drawing for handle

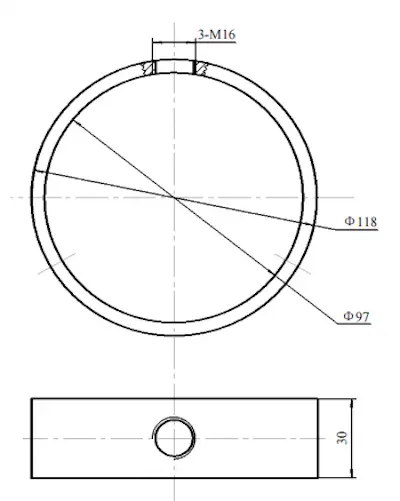

Figure 2 Drawing for Three-hole ring (for 95mm plug)

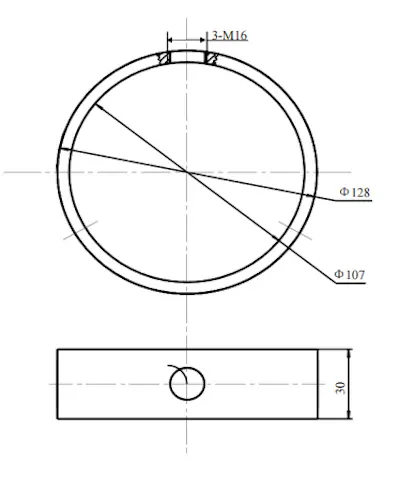

Figure 3 Drawing for Three-hole ring (for 105mm plug)

Figure 1 Drawing for handle

Figure 2 Drawing for Three-hole ring (for 95mm plug)

Figure 3 Drawing for Three-hole ring (for 105mm plug)

8. Field Application Analysis

Field Test and Application: Currently, all grassroots teams have been equipped with this device, which is easy to use, time-saving, labor-saving, and efficient. Notably, on November 29, 2020, the Yan 156-6 well, constructed by the seventh operation team, experienced a sudden overflow during the drilling process. The team used this device on the plug, shut down the well, and promptly control the overflow at the wellhead. Later, the team members expressed their relief, stating that without this plug valve rapid make-up and release device, the consequences would have been disastrous. According to on-site measurements, the time required to install the plug without using this device is 2.56 times longer than when using it, which is critical since time equates to safety in well control, and delays can be life-threatening.

Figure 2 Three-hole ring (for 95mm plug)

Figure 3 Three-hole ring (for 105mm plug)

Figure 2 Three-hole ring (for 95mm plug)

Figure 3 Three-hole ring (for 105mm plug)

9. Conclusion

The rapid make-up and release device for the plug is made from readily available materials, easy to process, simple to operate and assemble, and features a reasonable structure. Its on-site application has achieved the expected results. The successful development and widespread use of this device in the operating system are results of keen observation, diligent thinking, and bold innovation. The device has high practical value and plays a significant role in critical areas. Its innovation lies in the installation of handrails and steering wheels on the cock, allowing it to be quickly fastened and unfastened as needed. This device holds significant promotional value and has broad application prospects.